January 30 - February 6, 2016: Issue 249

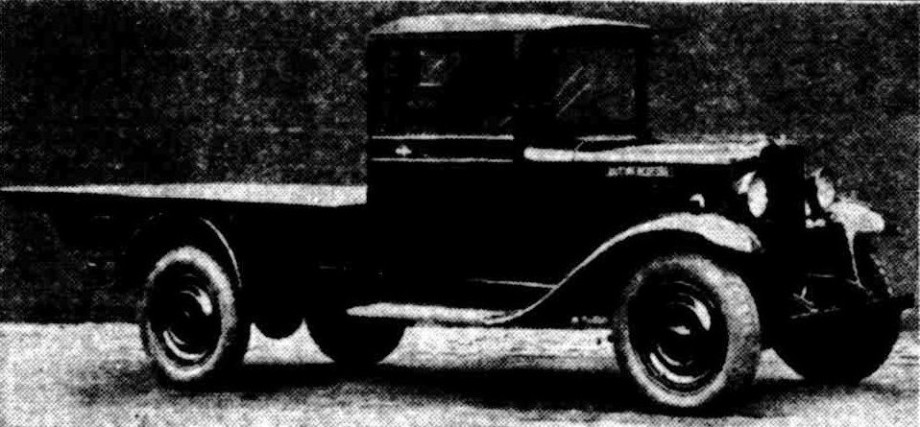

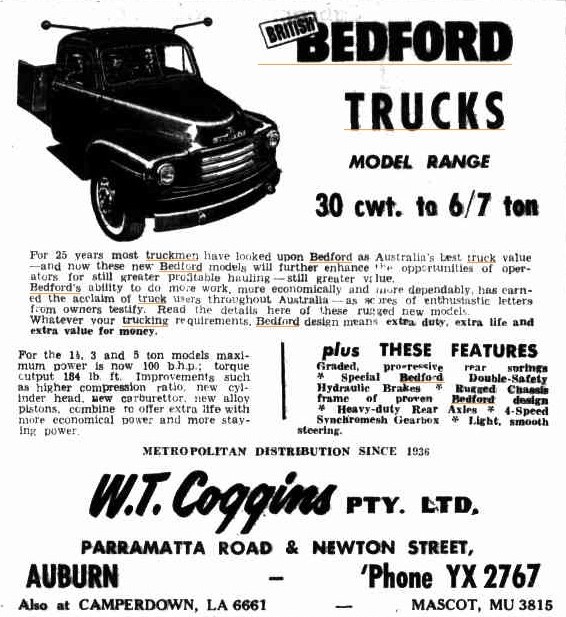

1958 Bedford 'D' Truck

1958 Bedford D Truck - photo by A J Guesdon, 10.1.2016

Classic cars have made regular visits to these pages, classic trucks have been harder to find …

Until a few weeks ago when we walked out the front of the office and found this beauty parked there.

It was a week before we lost founding Eagles member Glenn Frey on January 18th and yes, while taking the pictures the Eagle’s song ‘Take It Easy’ had already begun playing in the photographers head, there being a Soundtrack of the Mind that predominates each moment in the life of the happy snapper. How could it not when you see such a machine?

Such a fine sight to see

It's a girl, my Lord, in a flatbed Ford

Slowin' down to take a look at me

Come on, baby, don't say maybe

I gotta know if your sweet love is gonna save me

We may lose and we may win, though we will never be here again

So open up I'm climbin' in, so take it easy

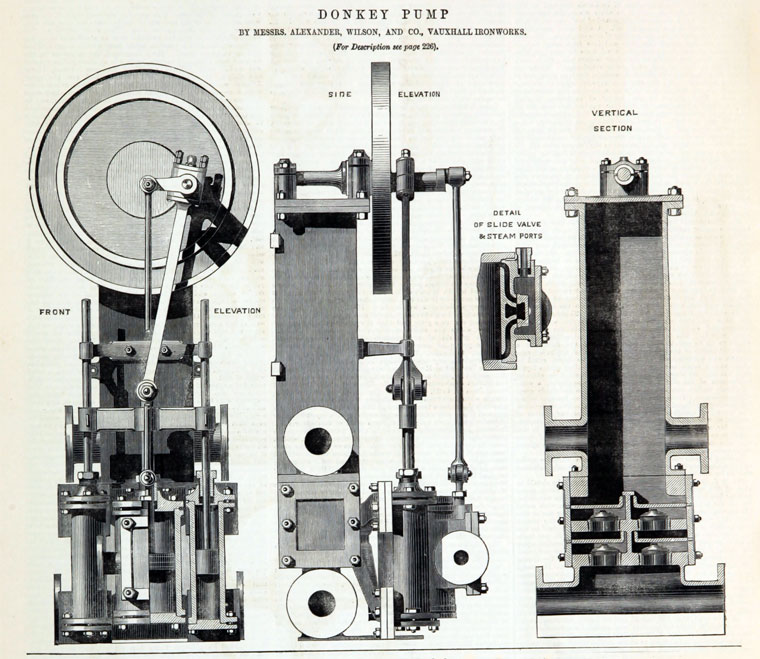

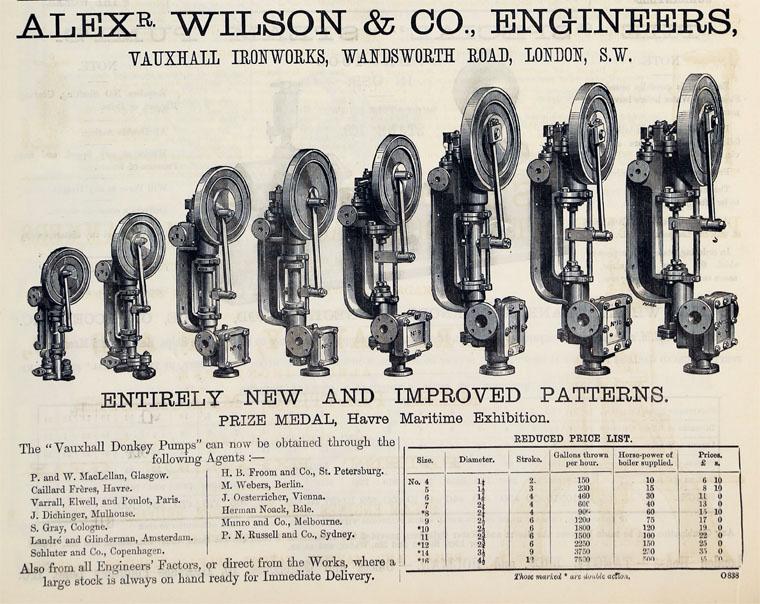

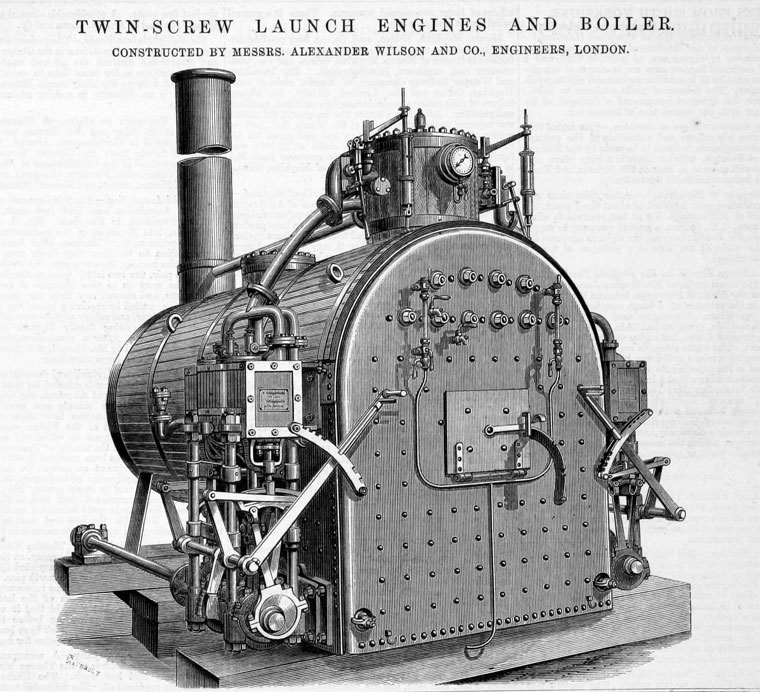

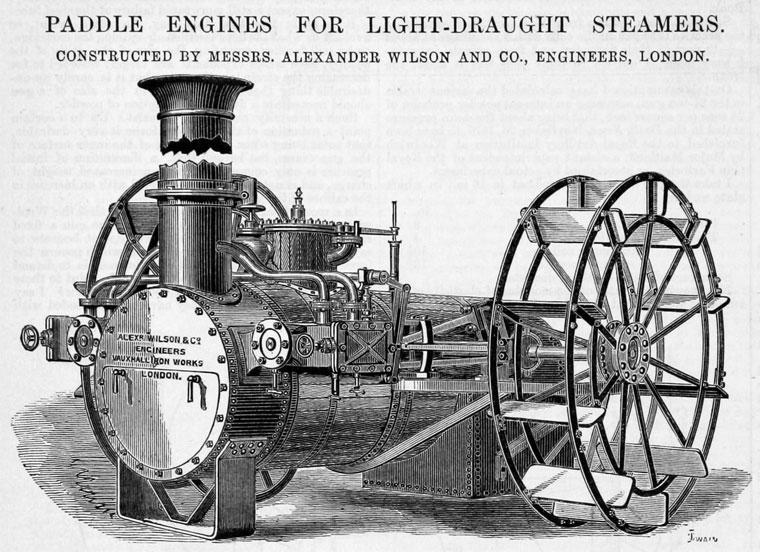

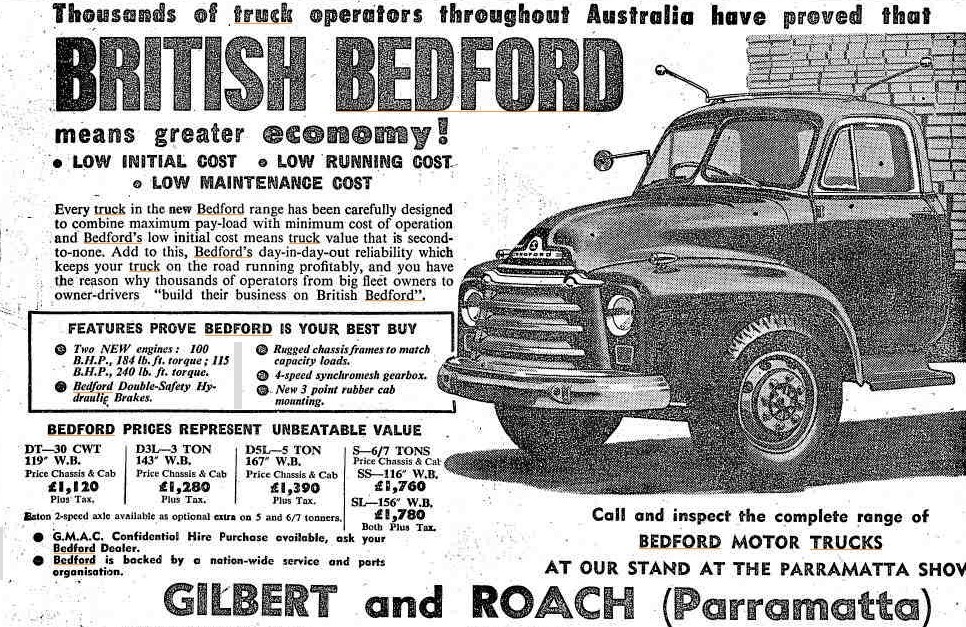

Bedford Vehicles, usually shortened to just Bedford, was a brand of vehicle produced by Vauxhall Motors, with the first truck produced in 1931. Originally founded as Alexander Wilson and Company by Scottish marine engineer Alexander Wilson at 90–92 Wandsworth Road, Vauxhall, London in 1857, and renamed Vauxhall Iron Works from 1897, the company built pumps and marine engines and some sources indicate he employed 95 men and 24 boys.

The etymology of Vauxhall is from the name of Falkes de Breauté, the 13th century head of King John's mercenaries, who owned a large house in the area, which was referred to as Faulke's Hall, later Foxhall, and eventually Vauxhall. The area only became generally known by this name when the Vauxhall Pleasure Gardens opened as a public attraction. These were originally known as 'New Spring Gardens', and believed to have been in operation before the Restoration of 1660.

The etymology of Vauxhall is from the name of Falkes de Breauté, the 13th century head of King John's mercenaries, who owned a large house in the area, which was referred to as Faulke's Hall, later Foxhall, and eventually Vauxhall. The area only became generally known by this name when the Vauxhall Pleasure Gardens opened as a public attraction. These were originally known as 'New Spring Gardens', and believed to have been in operation before the Restoration of 1660.

Extras:

STEAM NAVIGATION. BY MR. S. LYONS, On the Wharf of Mr. WILLIAM WALKER & Co. on Friday, the 31st instant, at 12 o'Clock, A MARINE STEAM ENGINE, of 16-horse power, by FAWCET of Liverpool. The specification may be seen, engine inspected, and other particulars learnt any day previous to the sale, by applying as above ; and Mr. LYONS calls the serious attention of tho enterprising Colonists to this opportunity of establishing, at a very small expense, a desideratum so much felt in the Colony as Steam Navigation. Classified Advertising. (1830, December 28). The Sydney Gazette and New South Wales Advertiser (NSW : 1803 - 1842), p. 4. Retrieved from http://nla.gov.au/nla.news-article2196867

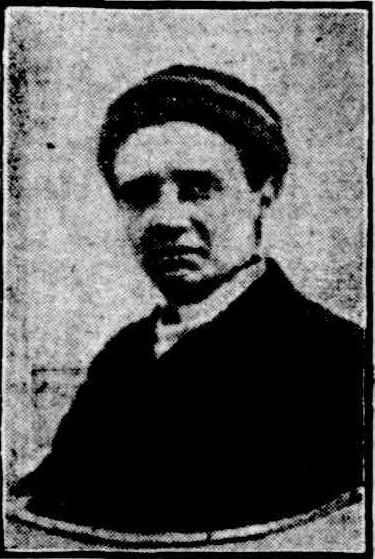

FOUNDER was “BETTER ENGINEER than ACCOUNTANT'

THE ORIGINAL FOUNDER of what is today the great Vauxhall organisation was a Scottish engineer, Mr. Alexander Wilson. He was described by one of his old employees as 'a better engineer than accountant,' because his desk was said to be covered by a mass of papers, which the office cleaner was instructed not to touch.

IN 1857 Mr. Alexander Wilson, founded a small business for the manufacture of marine engines at the Vauxhall Iron Works in Wandsworth Road, roughly five minutes walk from Vauxhall Junction. Trading as Alexander Wilson and Co. he acquired, within a few years, a well deserved reputation and employed some 150 men. His two main products were small, high pressure engines for Admiralty pinaces, and compound and triple expansion engines for use in river tugs. Engines were also manufactured for side paddle and steam wheeler ships and were refitted to two well known upriver pleasure steamers of the 90's— the 'Queen Elizabeth' and 'Cardinal Wolsey' plying between Westminister and Hampton Court.

There were many other products. For instance, a range off 12 different sizes in donkey pumps for boiler feeding. Added to this was the manufacture of 'Lightfoot' dry air refrigerating plants used in the production of artificial ice and for cold storage.

Mr. Wilson was also prepared to undertake any other engineering proposition which interested him and he had early ideas on accident prevention; his 'Excelsior' steam driver: pump, of horizontal design with valve gears operated by triggers at each end of the power stroke, had no unprotected moving parts.

In 1892 a limited liability company was formed, and, whilst Mr. Wilson remained on the board, Mr. W. Gardner came in as Managing Director. Two years after the formation of the com[any, however, Mr. Wilson sought his independence again and established himself as a consulting engineer. The Vauxhall Iron Works continued to produce marine engines and production was subsequently extended to include the assembly-of the complete power unit, boilers, shafting, propellers, steampipes and all the necessary fittings.

In 1897 the name of the firm was changed to 'The Vauxhall Iron Works Company Limited,' an adoption of the name by which the factory itself was known. With this reorganisation came Mr. F. W. Hodges a marine engineer who had served his apprenticeship with Alex Wilson and Co. The first British car had been produced shortly before 1898 and Mr. Hodges was not slow to visualize the enormous opportunities which this new invention held. A car was obtained and thoroughly examined and studied with the idea of eventually producing an independent and improved design. The model had its engine at the rear, tube ignition and a belt drive. How far that sample was responsible for the first car built at the Vauxhall works, will probably never be known, but it certainly bore no relation to the original Vauxhall put on the market. The first step towards car manufacture was the production of a small, single cylinder engine with two opposed pistons. This engine was tested in Mr. Hodges river launch, the 'Jabberwock', and gave sufficiently good results to allow experiments to'- continue. Next came a complete car very much on the lines of subsequent models, but it never got beyond a few test runs. It had, nevertheless, served its purpose and provided some very useful information. THE STORY OF VAUXHALL FOUNDER was "BETTER ENGINEER than ACCOUNTANT". (1949, December 6). South Coast Times and Wollongong Argus (NSW : 1900 - 1954), p. 3 Section: South Coast Times AND WOLLONGONG ARGUS FEATURE SECTION. Retrieved from http://nla.gov.au/nla.news-article142262412

Vauxhall Steam Engines in Sydney Steamers:

TRIAL TRIPS OF NEW STEAMERS.

Yesterday at the invitation of Mr George Cromack a small party of friends were present at a trial trip down the harbour of the new steamerStormbird, which has been built under the supervision of Mr Cromack, for Mr Fraser. A description of the vessel was given in the "Herald " at the time of her launch from the yard of Mr. W.Holmes at M'Mahon's Point. She is a shallow draught vessel of 60 tons gross, with some accommodation for passengers, and is intended for the Gippsland Lakes trade. During her trial yesterday the Stormbird, which is fitted with imported engines from the Vauxhall Company, of London, steamed the measured mile at a speed of nine knots per hour. Mr. Self (the Government inspector) who was on board, gave the result as 110lb. of steam, 26m vacuum, and 200 revolutions, Mr Fraser expressed himself well pleased with the trial. He leaves on Saturday for the lakes.

Another newly-built craft, the Woy Woy, a very shapely vessel from Mr W. Dunn's yard, Berry's Bay, was out yesterday upon her maiden trip. She is intended for the Gosford trade, and is owned by Mr. Charles Stephenson. Her yacht-like appearance was noticed as she came into the Quay. The Woy Woy, though not out for her official trial, went easily over the mile in 6 minutes, equal to a 10-knot speed, but she has a guarantee of another knot, and Mr. Stephenson, who was present, said that he was thoroughly satisfied with his really graceful little vessel. A not excessive shear or spring has been given her by Mr. Dunn, just enough with her symmetrical lines to make her attractive. At the conclusion of the trip Mr Stephenson was complimented by many of his Gosford and Brisbane Water friends upon his new boat. TRIAL TRIPS OF NEW STEAMERS. (1901, October 3). The Sydney Morning Herald (NSW : 1842 - 1954), p. 9. Retrieved from http://nla.gov.au/nla.news-article14413373

Vauxhall motor cars - almost 100 mph in 1912!:

MOTORING. By 'Spark.’

A MEMORABLE DAY.FIFTY MILES IN THIRTY MINUTES.BY A VAUXHALL.

Towards the end of the year, when misty mornings have fairly set in, favourable days for record breaking at Brooklands are infrequent, and when they occur are seized upon eagerly. November 4, though not a perfect day, owing to the direction of the wind, for .lowering the half-mile (or short) record, was at least clear and bright, and raised the hopes of a small party which had been awaiting an opportunity at Brooklands to try the pace of a 20 h.p. Vauxhall racer.

The famous racing track on an occasion like this is deserted save for a few officiate and those who in various capacities are interested in the event about to take place. Perhaps' not a dozen persons are to be seen. The enclosure, where hundreds of cars of all sizes and makes are ranged on a race day are empty. There is no shouting of bookmakers, no cheering of spectators, no crowd shift in from one point of vantage to another. In this state of' solitariness the great race ground, with its circuit of three miles, looks more spacious than at any other time, and becomes in spite of its emptiness more impressive. One realizes better the scale of it. The eye passes from the offices, the paddock, the grandstand, to the large aviation colony in the middle space— which makes so admirable a flying ground— and still further afield to those dark dots which represent labourers at Work on fanning of some sort -within the sweeping circle of cement.

The originator of this remarkable motor track must be a man of no small imaginative power and of great faith, to have conceived the possibilities of such an undertaking and to have had the courage to carry it out. His foresight and resolution have been justified by the result, for the Brooklands Automobile Racing Club is an institution which has enormously aided the development of motor construction in England. To Brooklands the French ascribe the fine work done by the English cars in the 'Coupe de Auto' race ' this year, and this belief is to be acted on during 1913,when many French drivers will be seen on the Weybridge track practising for their road races. It cannot be questioned that Brooklands' has encouraged the building of small engines of high . efficiency, such as the Vauxhall, the Sunbeam, the Straker-Squire, the Singer, and several more. The former two, in particular, have made excellent use of the facilities Brooklands affords for testing high-speed machines. And it is these two cars which are chiefly concerned in the attempt the Vauxhall firm is making today, with Mr. A. J. Hancock up, to recover one or two records which it had long held.

The exact position of affairs may be recalled. In the recent race (September 28)for the O’Gorman trophy— accounted the blue ribbon of the track— the Vauxhall had gained an easy victory; winning at an average speed of 92 ½ miles per hour over the distance of 30 miles, and beating the record. It was generally regretted that the Sunbeam car had not taken part in this race, which twice previously the Vauxhall had won. After the O'Gorman race again, there were expectations that a match, for which it was reported Mr.Gordon Watney was prepared to put up a prize of £100, would be run off between the two cars. This meeting, likewise, did not come off. But subsequently Mr. D. Resta brought his 155 h.p. Sunbeam down to Brooklands and surpassed the remarkable performance of the Vauxhall in the O'Gorman race. Both cars, by the way, notwithstanding the nominal difference of power, are of practically the same cubic capacity, the Vauxhall being indeed, very slightly smaller. Such being the state of affairs, it will be realised that the keenest interest is felt by those present as to what the next few minutes will bring forth. Those minutes will reveal whether the O'Gorman Vauxhall is the flier which its designer, Mr. L. H. Pomeroy, and its driver, Mr. Hancock, believe it to be. Hancock has been round for a 'pipe opener,' is satisfied, .and now but waits the signal to go. Admire for a moment the smooth, flowing lines of his machine, its handsome shell of polished aluminium, and try to realise that this small vehicle is capable of a 100-miles-an hour sprint. All is ready. The flag falls. The car bounds forward, shooting into the distance like a projectile impelled by terrific force. Going, well? Magnificently. First round in just over two minutes. The pace warms. Next circuit in less than one and three-quarter minutes. Then faster and still faster, the fourth lap being done in one minute and '41 seconds.

Right: Mr. A J Hancock - the well-known English racing motorist. He occupies the position of assistant works manager at the Luton wprks

Right: Mr. A J Hancock - the well-known English racing motorist. He occupies the position of assistant works manager at the Luton wprks

‘Lapping at ninety-eight and a half—rather more,' some one says. The watchers look on with breathless attention. The E class 50 'miles 'record is 'the objective, but this is good enough 'for a' world's record. Now the laps are being covered with wonderful' regularity— wonderful at least -to the lay mind, though .at Luton, where the Vauxhalls are -built, one would be '; told' that nothing - else was to be expected. There is no variation from lap four until lap 16, when the wind gets up and the time rises a second per lap. The wind increases as the last few miles are being run, yet Hancock 'flies over the line for the last time at a Pace still within 15 seconds of the best rounds. 'Thirty minutes fifty-two seconds. This equals a speed of 97.15 miles per hour. The ' world's record ; is 92.96 miles per hour;. E class record 79.19 miles per hour. Splendid! The Vauxhall is an first class machine, but it has beaten the bigger machine which set up the world's record. It has four cylinders of 89.7 mm. bore by 118 mm. stroke. The 30 h.p. Sunbeam that made the above mentioned world's record of 92.96 miles per hour, had ax cylinders of 90 mm. bore by 160 -mm. stroke. Incidentally the Vauxhall has captured the kilometre, mile, and the long (10-lap)records in E class, and has automatically improved on its record in the 21 h.p.(R.A.C. rating) class. This much-coveted long record is now a Vauxhall possession in both classes, as it has been in the 21h.p. R.A.C. class since October. 1910,.though the figures were temporarily exceeded in October, 1912, by the E class Sunbeam.

All is over except the measuring. The base chamber is removed. Mr. Lindsay Lloyd, the courteous official timekeeper to the club, slips off his coat, rolls up his sleeves, clambers beneath the up tilted car, and lying on his back in a position, it is to be feared, of some discomfort, proceeds with his instruments to verify the dimensions of the cylinders. This done, the stroke is measured.

'All in order,' reports Mr. Lloyd. 'Go ahead and advertise as much as you like. By the way, be careful not to say that you have got a world record. You have beaten it, but the international federation has to pass the claim.'

This federation meets once a year in Paris. So ends a red-letter day on the Brooklands track, for never before has the 50miles world's record been lowered by a 20-h.p. car. It. was for long held by a 60 h.p. and then for a few weeks by a 30h.p. car. Now a 20-h.p. car has entered the arena, and its success is a tribute to the merits of the Vauxhall design. Records come and records go. Hardly were these, lines written ere , a 60-h.p.Excelsior improved on the Vauxhall figures by 1m 31s., attaining an average speed of 102.36 miles per hour. But the value of the Vauxhall performance, is by no means diminished. The difference is the size of the engines is to be borne in mind, though in determining a claim to a world's record engine size is set aside. A 25-h.p. Talbot and engine about 40per cent, bigger than the Vauxhall, has since (November 16) accomplished the amazing speed of 113' miles per hour for the flying half-mile— though it did not last more than three laps — a speed which surpasses any written down in the Brooklands record books save that of the big 85-hJp. Benz. which has done the half-mile at nearly 128 miles'' per hour. ' Thus the Vauxhall record remains as a feat never before performed by a small engine, and by comparison the finest, for the 20h.p. Vauxhall comes well within the 'French three-litre class.' and its pace is very little behind the Best that has been achieved by the latest 60-h.p. record breaker. MOTORING. (1912, December 28). The Mail (Adelaide, SA : 1912 - 1954), p. 5. Retrieved from http://nla.gov.au/nla.news-article58188519

British Motor Industry - Result of Protection

Manufacturers of motor-cars in Great Britain naturally welcome the re-imposltion of the "McKenna" duties. Application had already been made bytho Association of British Motor Manufacturers, Ltd.; for protection Under the Safeguarding of Industries Act, and now that protection has been afforded, at least to tho passenger vehicle section of the industry, a still further expansion can with confidence be predicted (states a bulletin of the Department of Overseas Trade)." Plans that were laid aside when the duties were repealed last August will eventually be put into operation. It Is not fully realised that the production of motor vehicles in Great Britain at the present time, 129,990 per annum,- is at least ten times greater than it was before the war. The Industry was, of course, virtually in abeyance during the war, and tho recovery and expansion were made possible by the protection originally afforded by the McKenna duties. This increase in output has only been brought about by a complete revision of manufacturing methods, and as output has increased prices have been consistently reduced. Approximately 75 per cent of the motor-cars sold In Great Britain during 1924 were of British manufacture; two years ago the percentage was about 59, and as a further share of the home market is now secured to the home producer, an additional Increase In output with a further fall in prices may be expected. The home market is, of course, the largest and most important market for the British manufacturer, and there is really no reason why he should not wholly meet the demand. Protection will undoubtedly lead toa reduction in prices. Several of the leading manufacturers, such as the Daimler Co., Ltd., and Vauxhall Motors Ltd., have already announced very substantial reductions in the prices ' of their cars, "Daimler" cars have been reduced by amounts varying from £125to £309; "B.S.A." cars by from £60 to£85, and "Vauxhall" motors by amounts up of £61. These reductions are due to the resumption of programmes for extended manufacture. Before the Budget proposals were announced prices were tending to become stabilised, and any reductions would probably not have taken place until the Motor Show in October, or the beginning of the selling season next year. A case which indicates the tone of the market is that of tho 14h.p. Crossley; the price Increased early this year to £435, and has now been reduced to £395.Reductions in the price of both Imported and British cars took place in anticipation of, or after, the repeal of the duties last August, but it is now generally admitted that such reductions were largely fictitious If the duties had not been repealed greater reductions would have taken place, since prices in the home market are now undoubtedly controlled by the keen competition existing between British manufacturers themselves. The absence of the duties caused a halt in production plans and a consequent halt in the lowering of prices. As soon as the budget proposals were announced those who have not the interests of the British motor industry at heart — and they are many — stated openly that protection -would lead to higher prices. Recent price movements have, however, proved such predictions to ho false. It is even doubtful if the duty on imported vehicles can now be passed on to the consumer so strong and so firmly entrenched is tho position of the British motor-car. Though the British manufacturer has had to meet severe competition, particularly from the Continent, where depreciated currencies and rates of exchange favour the importer, during two selling' seasons he has not lost ground.' A' halt only has been made, and when conditions become stable again he will go forward and with the home market at his disposal he will turn his attention to markets overseas. The export of motor vehicles, including chassis, for the months January-April this year numbered 8,42-3, representing an increase of 4,781 over tho corresponding period last year The export of motor-cars from Great Britain will again this your establish a now record. MOTORS AND MOTORISTS. (1925, October 6). The Telegraph(Brisbane, Qld. : 1872 - 1947), p. 12. Retrieved fromhttp://nla.gov.au/nla.news-article177080988

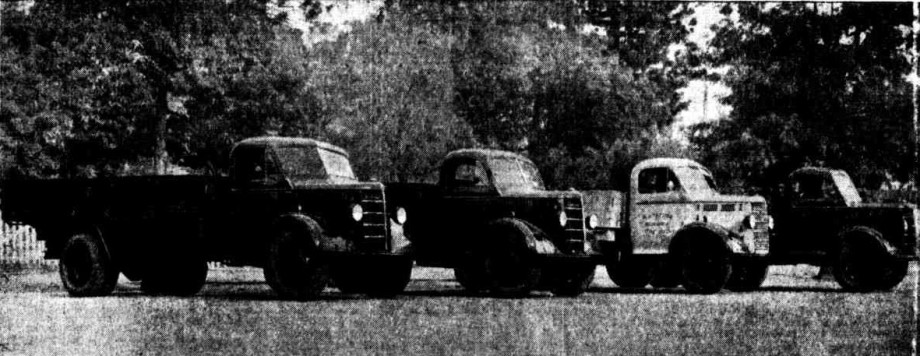

World War Two Effort by Vauxhall-Bedford

Vauxhall’s Vast Volume OVER 200,000 BEDFORD LORRIES

VAST production figures were achieved by Vauxhall Motors Limited, in its wartime work, which we are now able to summarise and illustrate. The works which in peacetime claimed such a high percentage of British lorry building employed some 12,000 people, and turned out Bedford trucks at a rate close on 1,000 a week. From September 3, 1939, to VE-Day no fewer than 209,096 vehicles were delivered to the Forces-so that about one in three of Army trucks were Bedfords-on top of which thousands of civilian models and 32-seat buses were supplied to meet urgent needs. The models delivered were the15-cwt., 30-cwt., and 3-ton (Army ratings) of conventional design, with only the rear wheels driven, and also an entirely new Bedford 3-tormer-theQL type-with two live axles. For normal use power was applied to the back wheels only, but on sand, mud or other bad surfaces the front wheels also could be driven.

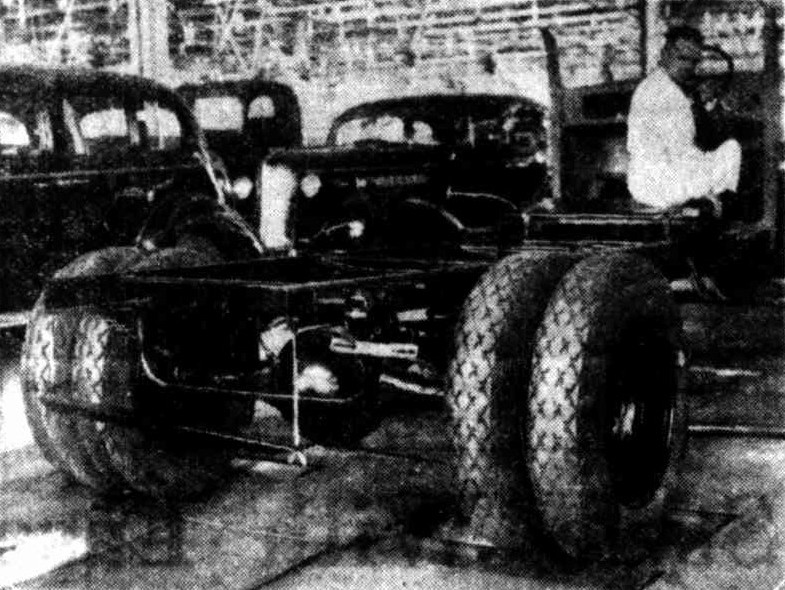

Besides actual vehicles, colossal quantities of spare parts were called for by the Services. To December, 1939, Vauxhall delivered parts worth a quarter of a million pounds; in 1944 the deliveries were worth five and a half millions. The total value of all parts supplied throughout the war was £18,450,156. The number of major assemblies required ran into some thousands, including 28,430 engines.10,512 front axles, 11,149rear axles, 11,728 gear-boxes, 3,013 transfer boxes, and 11,459 steering gears. As space was not available for prepacking and preserving spares at Luton, the company had to do this job with Ministry of Supply labour and factory in Walsall. Between November, 1943,and April, 1945, four mil-lion cartons, each containing anything from one to thirty or forty pieces, were supplied. All major assemblies had to be packed in specially ap-proved cases, constructed to stand up to any amount of abuse. In fact, the engine, when packed, had to withstand being dropped from a height of last a resilient wheel, little to be distinguished in riding quality from a pneumatic-shod unit, was evolved by Vauxhall. But the rubber situation did not turn out quite as desperate as feared, and large-scale production never began.

The Vauxhall resilient wheel, designed to replace pneumatic tyres if need arose.

Another endeavour, brought to an end by the collapse of Germany, was the Bedford tractor for heavy guns, a tracked vehicle with steerable front wheels. Only three pilot models were completed. It could tow a Bofors, a 17-pounder pr a 25pounder and stow the ammunition of each equally well. The power unit was two Bedford engines coupled in V formation by gearing at the input of the gearbox.

MANY TASKS

Many varied tasks in the Vauxhall works included the production of parts for the stream-lined petrol cans-christened by Mr. Thomas Atkins the "Jerrican"-used in the later stages of the war. Vauxhall turned out 5,000,000 pressings for sides of these cans, representing 2,500,000 cans when welded up. Actual assembly had to be carried out by other firms, as will be realised when it is said the weekly production rate rose to65,000. Venturis for rockets were another difficult pressing which speeded up the older' production processes considerably.

Within six weeks of the company being approached the press shop turned them out at 50,000a week; this figure rose to 70,000 weekly, and altogether over 4,000,000were made. .

In an emergency Vaux-hall was asked to make ammunition for the six pounder gun which aided our success from El Alamein onwards. Armour piercing shells were sought, and here, again, six weeks from the start, the Vauxhall output wasbig-5,000 a week. In all250,000 rounds were de-livered. Another speedy feat was the design of the20-mm. gun mounting, suitable for towing behind or carrying upon a lorry. As the company's works were overtaxed, after 100mountings had been six to eight feet. (An article on tropical packaging and preservation appeared in our August 4 issue.)

CHURCHILL TANKS

One of the best-kept secrets of the war was that Vauxhall Motors Limited was responsible for the production of the 33-ton Churchill tank. Starting from scratch, the company had hand-built pilot models running in six months, and production tanks coming off the line in exactly a year. In that period the tank had been designed, anew factory erected, sources of supply for materials established, tools and equipment designed, obtained and installed. In addition to producing Churchill tanks in its works at Luton, the company acted as parent company and providers of materials to Testing waterproofing on a Bedford 15-cwt. (Army rating) in a 7-min. dip, up to 4ft,J Gin. deep; a test on a Churchill; below, instructing Czech soldiers in Bedford overhauls right, testing a Bedford W.D. lorry on rough ground.

the following ten companies, all of which also built Churchills:

The Birmingham Railway Carriage and Wagon Co. Limited.

Beyer, Peacock and Co. Limited, Manchester Broom and Wade Limited, High Wycombe. Dennis Bros. Limited, Guildford. The Gloucester Railway Carriage and Wagon Co Limited, Gloucester. Harland and Wolff Limited, Belfast.Leyland Motors Limited, Leyland. Metropolitan-Cammell Carriage and Wagon Co Limited. Wednesbury. Newton Chambers and Co. Limited, Sheffield. Charles Roberts and Co. Limited, near Wakefield

In all 5.247 Churchill tanks were delivered by the group. As various improvements were introduced and new equipment added-more powerful armament for example-earlier model? were sent back to be brought up to date, and Vauxhall stripped and rebuilt 2,911 tanks. For the Churchill a special 21-litre 12-cyi. engine was designed with an output of 350 b.h.p. at 2.200 r.p.m

THE VAUXHALL WHEEL

The modern army does not so much march on its stomach as roll into battle on rubber Troops with their supplies and equipment, are carried in lorries. Even tanks are carried to the fighting zones on rubber tyred transporters. When Japan took from us the most prolific rubber-producing areas in the world, the authorities decided chat if the worst came to the worst we must be prepared to operate lorries without rubber tyres. Whatever happened, we would fight on. So they called upon the motor industry to develop a spring wheel. At the experimental department the work was passed over to other firms, but production jigs and fixtures were provided by Vauxhall, which also did sheet metal work. The gunner's seat, in sheet metal, which would have taken 18 hours to shape by hand, was, as a result of Vauxhall tooling, turned out in three minutes.

JIGS AND DIES

As Vauxhall had highly skilled craftsmen in its die department, and the sheet metal tooling capacity was beyond the firm's wartime requirements, 30 per cent, of the work of this section was for other firms and from Government Departments. No fewer' that 4,673 dies and jigs for air-craft and naval construction, from master templates weighing ounces to complicated structures weighing many tons, were produced. They went into aircraft, torpedo, ammunition, mines and lifeboat construction.

Odd jobs to help out other manufacturers who were experiencing bottlenecks in production included all sorts of general engineering jobs on such diverse items as 50,000 disc harrows. 250.000 bomb-eases, arid 100,000 land and sea mines. Concrete mixers, mortars, gas ovens, hand grenades and rifle pull-throughs shared in such attentions. The company's Hendon packing plant packed 12,000export vehicles from the outbreak of war until July, 1940. and then assembled imported vehicles until the summer of 1941 Engine reconditioning then held the field m the packing plant the rate rising this year to 10,000 a year The total delivery to VE-Day was 22.199 Bedford engines over-hauled and restored to service with the Services. Other units were handled in the spare time of this comparatively small plant In addition Hendon plant packed over 13.000 vehicles for Russia, the Near East and North Africa, and Hendon and the experimental Coles Green packing unit unboxed and assembled 5.432 vehicles imported from overseas. Finally let us mention that 200,000 officers and other ranks received instruction, in the field or in the factory, from Vauxhall instructors, and over 2,250,000 books and charts were issued for instructional purposes, the company taking special measures to find out reactions in service of Bedford lorries. Churchill tanks, and other products so as to issue suitable instructions. PRODUCTION FOR WAR. (1946, May 16). The Mercury(Hobart, Tas. : 1860 - 1954), p. 20. Retrieved from http://nla.gov.au/nla.news-article26196293

AUSTRALIAN BUILT BODIES. ACCURACY THE KEYNOTE.

From the raw material to the finished product every production operation in the manufacture of passenger car bodies for the products of General Motors is conducted under the vigilant supervision of inspectors at Holden's Motor Body Building Plant at Woodville, South Australia.

All bodies are built in accordance with General Motors policy of quality production and to designs supplied by General Motors, those designs embodying requirements and characteristics of the motoring public of Australia. Each new body model is an improvement over the previous ones. This is the result of consistent steady progress along the right lines. The fact that of the total output of bodies from Holden's Motor Body Building Plant, the major portion are manufactured to fill the requirements of General Motors (Australia) Pty, Ltd., is the result of motordom's empathic and lasting endorsement of design, manufacture and manufacturing methods. It is also both a significant tribute to the expansion made in Australia in motor body building as well as to the skilled workmanship of the thousands of Australians engaged in this important Australian industry. The entire staff of Holden's Body Building Plant is composed of Australians, all of whom play an important part in the incorporation of salient features that contribute to the popularity of these Australian-built bodies. The first procedure in the building of motor bodies in the provision made to assure requisite dryness of all timber used in manufacture. The timber is first sorted into various sizes and stacked on steel trucks. When it is required for. use, these trucks are run on rails into the drying kilns where the timber remains until thoroughly dry. Samples are then tested toi definitely ascertain that no surplus moisture remains. At the same time the timber is tested for size, as' shrinkage takes place in the process of drying. It is then run on the same trucks to the mills where the trucks are placed on timber lifts. These timber lifts are then lowered into concrete lined pits in the earth, lowered until the timber at the top of the stack remains above the top of the pit a sufficient height to make for ease of handling. It is maintained always at this level; as timber is taken from the top of the stack so the lift is raised. These timber pits constitute the most approved method of handling in use in foremost motor body building plants, a ;method attended by easy efficient handling. As timber is required it is put over the swing saw and cut into essential lengths.

The timber in its various lengths then goes through the various wood milling operations until it reaches completion. These operations may include: — Rip sawing, Planing, shaping, tennoning, drilling. The timber during the above operations is placed in what is known as a mill form from which each piece emerges identical in size. This process is one of absolute accuracy. When they come out of the mill form the pieces of timber are all ready for assembling and when assembled do not require further working. The next procedure is the placing of the Umber in the store ready for use. Coincident with the preparation of timber steel sheets especially made for motor body building purposes, are being cut to the right size and then placed in the stamping press,- where they are pressed to the required size shape. In the next process they are trimmed all round the edges and any surplus metal removed. They then pass to small punch presses where any holes required are punched in. This process also includes the punching of small holes required for nails in the affixing of the sheet metal panels to the wooden frame. Meanwhile work proceeds with smoothness and accuracy in the body framing department, where by means of jigs all requisite pieces of timber are framed and screwed together, all joints being double glued. These jigs also provide absolute accuracy of measurement so that all bodies framed on each jig shall be identical in every particular. As the body comes of the framing jig it is placed on a steel truck and remains on this truck until it 4s completely finished. The frame completed, the next operation is the consolidation of steel metal panels to the wooden frame, after which comes the hanging of thee doors. In turn is the metal finishing operation by which all metal is thoroughly smoothed of preparatory to the bodies being sent forward to the Duco Department. In the duco operation, the bodies are first thoroughly cleaned. Next the undercoats are sprayed on. Bodies are then dried by passing through an oven. The next process constitutes their sanding and smoothing off in preparation for coats of Duco. After the Duco has been sprayed on, the bodies are again allowed to dry, and finally are polished with special polishing compound. Having been Ducoed, the bodies next pass to the trimming shop, where the cushion springs and upholstery are fitted inside the body. So far as the open models are concerned, the hood is built and fitted to the body on the trimming line, the bow sockets being erected and the hood material stretched over. The upholstery is fitted before the hood is built. The procedure in fitting the upholstery is to take the doors first, then the sides, next the backs. The seats are upholstered separately to the body and placed in the body after all the other trimming is in. The upholstery is

Also prepared in the cutting and sewing room. The cloth is laid on a long cutting bench in so many layers and cut by electric cutting machines by method illustrated. It then passes on to the sewing machines in which sewing illustrations are carried out. These sewing machines are also electrically driven. Finally the hardware, such as door handles, robe rails, foot-rests, etc., is fitted. Having been completed in the trimming shop the body is then ready for the final inspection which is made by a staff of qualified inspectors who must pass all bodies as correct before they are packed for delivery to the various Australian assembly plants of General Motors (Australia) Pty. Ltd. Needed expansion is taking place at Holden's Motor Body Works, which will both enable output to be increased and more Australian workmen to be employed. The high grade coach-Work turned out provides a striking example of the adaptability of Australians in this comparatively new industry — that of building high class bodies for reliable chassis such as the(products of General Motors. As regards constructional details and the

excellence of the standard maintained. so too the character of finish that distinguishes all bodies produced is at ail times a quality finish. Holden’s Motor Body Building Plant is now armed with the sinews of trade and can translate the most modern ideas, into .vigorous practice. New developments are constantly being made so that production shall move more smoothly and economically. The progress of the body building industry Australia has, therefore, been largely due to the extensive requirements of General Motor (Australia)| Pty. Ltd. However, this enterprise| could not have grown to its present large dimensions without the adequate response of Australian workmen. supervised by able Australian executives. The combination of a high character design such as characterises all requirements for bodybuilding in alliance with General Motors' products, and ambitious and skilled Australian craftsmen is resulting in great strides being made in the body building industry in Australia. AUSTRALIAN BUILT BODIES. (1928, March 10). South Western Times (Bunbury, WA : 1917 - 1929), p. 3. Retrieved from http://nla.gov.au/nla.news-article210787854

Rise of An Industry - From Saddles to Motor-bodies

By CHARLES FORD

IN two decades the building of bodies for motor-cars and motor-trucks in Australia has sprung from nothing to one of our greatest industries. It employs thousands of hands, and assembles enough private and commercial motor vehicles to meet the whole of Australia's requirements. The number of motor-bodies imported, to Australia is negligible.

The history of this thriving and expanding industry, which was born out of necessity, is virtually the history of General Motors Holden’s Ltd. from its lowly origin as a saddlery business to its present position as the largest organisation of its kind in the British Empire.

A survey of the history of the company is enlightening. In 1917,because of the German attempt to destroy Great Britain's mercantile fleet by submarine warfare, the Commonwealth Government restricted the importation of motor-cars to the bare chassis and engines.

The motor-car selling interests In Australia were then faced with the necessity of establishing a new industry in this country, and they entrusted the task of building motor bodies to Messrs. Holden and Frost, of Grenfell street, Adelaide, a saddlery firm which has been in business for 50 years. In that way the organisation, which now owns the largest motor body building plant in the British Empire, was born. In 20 Years

In 1926 a world-wide organisation, General Motors Corporation, established facilities in Australia for the marketing of motor-cars and the construction of plants in every capital city for assembling cars and trucks. General Motors (Australia)Pty. Ltd. was formed to operate that business.

By 1931 nearly. 70 per cent, of the output of the Holden factory was being used by General Motors. Ultimately a merger was arranged, and General Motors-Holden's Ltd., the present company, came into being. It now has assets worth between £3,000,000 and £4,000,000,and it has embarked on a vast programme of development, the end of which cannot possibly be predicted.

Just 20 years ago Holden's Motor Body Builders, which is the body building division of General Motors Holden’s Ltd., produced their first body, and during the first year the production totalled 99 units. Last year 32,494 bodies were built, which illustrates the progress that has- been made and the demand that has been created for the Holden product.

The company has five inter-locking plants in operation in Australia. The largest manufacturing activity is at Woodville (S.A.),where the company employs nearly 5,000 men. At this factory the car bodies which are assembled later in each of the capital cities are made, the output being about 170 a day.

Covers 40 Acres.

From a factory covering barely three-quarters of an acre this plant has gradually been increased in size, and to-day it is spread over 40 acres and occupies a little more than 1,000,000 square feet of floor space. To keep abreast of the ever-changing trend in body design and construction, executives of the company are constantly visiting overseas plants During the next few months the company will instal at Woodville new equipment valued at £160,000

This includes one of the largest presses yet built for the production of motor body panels This press which is now on its way to Australia, weighs 500 tons One section had to be designed specially so that it could be lifted from the ship by the 60-ton crane of the Port Adelaide Harbours Board

In the Initial design this heavy cast section of the press weighed 80 tons, but, in older to bung it with the scope of existing crane equipment it was reduced to 60 tons. A special trailer, with 24 wheels is being obtained from the eastern States to take the various portions of the press from the wharf to the plant at Woodville. The press is 23ft. high from the floor level, and extends 15ft. below the surface. It will exert a pres-sure of 1,000 tons, and will be able to produce a complete side, top, of floor of a motor-body in one action.

Cars are given a thorough "road test" at varying speeds on rollers set into the floor before leaving the General Motors-Holden's works at Fishermen's Bend.

Fishermen’s Bend

Fishermen's Bend is the home of the commercial body, as Woodville is the home of the car body. So diverse are the needs of operators that more than 150 distinct types of commercial bodies have been evolved, and they are changed constantly to suit local' needs and to keep abreast of overseas developments.

There are 1,000,000 car parts at the factory, and more than 50,000 different kinds. They occupy more than 50,000 square feet of floor space. The spare parts department has its own engineers and its own testing equipment. It must be ready to replace anything from a small nut to a complete engine assembly.

There are 1,000,000 car parts at the factory, and more than 50,000 different kinds. They occupy more than 50,000 square feet of floor space. The spare parts department has its own engineers and its own testing equipment. It must be ready to replace anything from a small nut to a complete engine assembly.

In the motor assembly factory mass-production methods contribute to an output capacity of 100 motor-cars a day, with a maximum total capacity of 120. Out of the mass of thousands of small parts a motor-car is made. Meanwhile the body service department is equally active. A continuous stream of cars is brought to this department for repairs, silencing, or cleaning. They may receive any form of treatment from a wash to a major surgical operation.

The building took only eight months to complete. It covers seven and a half acres of land and1,240 tons of structural steel were used in its construction. The artificial lighting system uses sufficient]electricity to supply a town with a population of 12,000.

The importance of General Motors-Holden's Ltd. is not restricted to the capital and labour employed directly by it in five States, or even to the community service performed by an output which supplies so large a proportion of the transport requirements of the Commonwealth. It gives an impetus to à wide range of industrial activities in all parts of the country, and each year it is the customer of more than 200 manufacturing firms.

Right: Spraying lacquer on the body of a commercial vehicle at the General Motors-Holden's works. The crafts-man is wearing a nose-guard as a protection from the fumes.

Defence Value

The company performs invaluable service in furnishing defence forces with the specialised mechanised transport on which any strategical plan for national defence inevitably depends. It has placed its full technical resources at the disposal of the Defence Department.

Another aspect of the company's business which is growing in significance is its export trade to the Orient, South. America, Egypt, and Africa. Formerly this market was commanded in most of its phases by Great Britain and the United States, but since 1933 the company has placed Australia's export trade to those countries on a firm basis. Rise of An Industry. (1938, July 29). The Argus(Melbourne, Vic. : 1848 - 1957), p. 5 Supplement: Twentieth Century Exhibition. Retrieved from http://nla.gov.au/nla.news-article12452267

MOTORING MOTOR CAR BODIES TWO-THIRDS MUST BE BUILT IN AUSTRALIA

By Bede Carroll

The appeal of the motor-car traders of the Commonwealth for certain concessions in respect of the order of the Luxuries Board, prohibiting the importation of motor-car bodies into the Commonwealth after August 10 last, has resulted in a compromise being effected. When the prohibition was ordered the trade rightly made vigorous protests to the Minister for Customs, Messrs. :'.. L. Tyler and C. H.Klostcr, representing this State upon several deputations. It was urged that the trade should be allowed to import all bodies then on order, and it was pointed out that the present body making firms in Australia could not possibly turn out sufficient bodies for the chassis imported. It has been decided that the importation of all bodies ordered prior to August 10 last, and which may be shipped from the factory on or before December 31 next, may be allowed. In the event of any trader desiring to import cars not ordered prior to the date of the proclamation, each complete car must be accompanied by two other chassis before it will be admitted into the Commonwealth. The motor-car bodymakers of Australia will therefore have the opportunity of supplying two-thirds of the number of bodies required by the trade, and, from all accounts, this is likely to be beyond them. MOTORING. (1917, October 21). Sunday Times (Sydney, NSW : 1895 - 1930), p. 13. Retrieved from http://nla.gov.au/nla.news-article122789076

Saddlers' shop became a national industry

In Adelaide 60 gears ago there was an efficient and enterprising saddler named Henry Holden, who, in partnership with a man named Frost, went into business as a coachbuilder.

OUTSIDE his premises in Grenfell street he set up a life-size white horse that became an Adelaide landmark. The business prospered and, by the time his son, Edward, came into it in 1907 there were 120 workers. From coach building the firmturned, with the years, to building motor bodies; first one or two at a time, and then in large numbers. Young Edward,who had been to the university*no [got a degree in science, was proving, also, a man of business.The motor body building soongrew too big for the saddlers'?hop.In 1917 a new company, Holden Motor Body Builders Ltd.,was formed.

Production jump

A factory was taken over to King William street— on the site where Myer's bulk store now stands. By the end of the year two open tourer bodies had been produced.From then on production figures spiralled. In 1923 more than 12,000 bodies were turned out— and a start was made on the Woodville plant..Finally the firm was turning them out on mass-production belts at the great plant, which now covers 55 acres.It was then that Edward Holden took a trip overseas, and talked General Motors executives into an agreement to turnout all their Australian requirements.This was in 1923, and a few years later came the big depression. It took all the ingenuity of Edward Holden to keep the great plant working.He did it by making fruit cases, golf heads, and filing cabinets.Thus, when better days came, Holden's of Woodville was intact, and there - came the merger that resulted in one of Australia's greatest industrial enterprises— General Motors Holdens.When war came the firm was equipped for a major part in Australia's war production.When Sir Edward Holden died last year, nearly 10,000 people were working for his firm. A third generation took over, and nephew Mr. J. R. Holden is now chief executive of the Woodville plant.This week General Motors Holdens announced the new Australian car it has developed would take the name of Holden as a tribute to the family who built a business from humble beginnings to the mammoth concern it now is. Saddlers' shop became a national industry. (1948, September 4). The Mail (Adelaide, SA : 1912 - 1954), p. 23. Retrieved from http://nla.gov.au/nla.news-article55898888

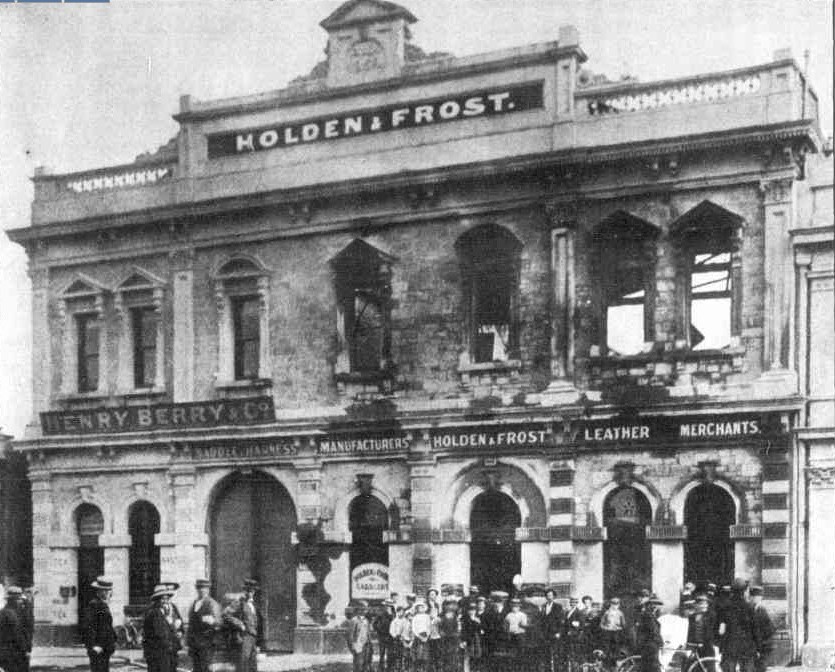

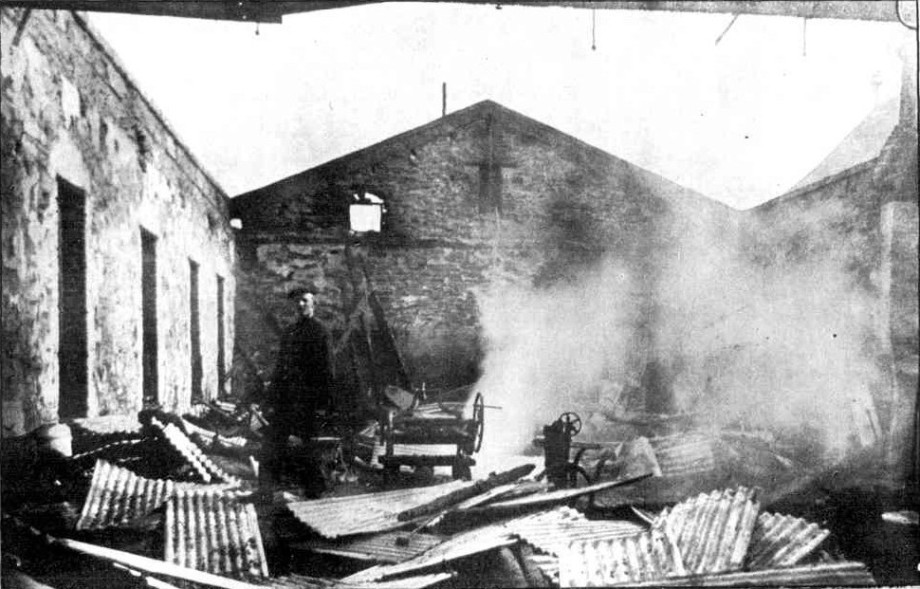

MESSRS. HOLDEN & FROST'S SADDLERY ESTABLISHMENT IX GRENFELL-STREET. PARTIALLY DESTROYED BY FIRE ON TUESDAY EVENING, FEBRUARY 10.

THE FIRE AT MESSRS. HOLDEN & FROST'S: AN INTERIOR VIEW.

DRINK LEGISLATION. (1903, February 14). Chronicle(Adelaide, SA : 1895 - 1954), p. 44. Retrieved from http://nla.gov.au/nla.news-article87840172

Taking it Easy

"Take It Easy" is a song written by Jackson Browne and Glenn Frey, and recorded by the Eagles with Frey singing lead vocals. It was the band's first single, released on May 1, 1972. It peaked at No. 12 on the July 22, 1972 Billboard Hot 100 chart, after debuting at No. 79 on June 3. It also was the opening track on the band's debut album Eagles and it has become one of their signature songs, included on all of their live and compilation albums. It is one of The Rock and Roll Hall of Fame's 500 Songs that Shaped Rock and Roll.

Jackson Browne, who began with The Nitty Gritty Dirt Band, an American country-folk-rock band, in 1966, later recorded the song as the lead track on his second album, For Everyman (1973), and released it as a single as well, although it did not chart. Travis Tritt also covered the song for the 1993 Eagles' tribute album Common Thread: The Songs of the Eagles, the video for that song is notable for the appearance of all five members of the Eagles together the first time in 13 years after their break-up, and led to the reunion of the band a few months later.

Jackson Browne originally began writing "Take It Easy" in 1971 for his own eponymous debut album but was having difficulty finishing the song. His friend and then-neighbor Glenn Frey heard an early version and later asked Browne about it. Browne then played the unfinished second verse that begins with "Well, I'm a-standin' on a corner in Winslow, Arizona, such a fine sight to see", and Frey finished the verse with "It's a girl, my lord, in a flatbed Ford, slowin' down to take a look at me." The resulting song became the first track on the band debut album and was released as their first single.

Browne told a version of the story in a radio interview, praising Frey: "I knew Glenn Frey from playing these clubs - we kept showing up at the same clubs and singing on the open-mic nights. Glenn happened to come by to say 'hi,' and to hang around when I was in the studio, and I showed him the beginnings of that song, and he asked if I was going to put it on my record and I said it wouldn't be ready in time. He said 'well, we'll put it on, we'll do it,' 'cause he liked it," Browne explained. "But it wasn't finished, and he kept after me to finish it, and finally offered to finish it himself. And after a couple of times when I declined to have him finish my song, I said, 'all right.' I finally thought, 'This is ridiculous. Go ahead and finish it. Do it.' And he finished it in spectacular fashion. And, what's more, arranged it in a way that was far superior to what I had written."

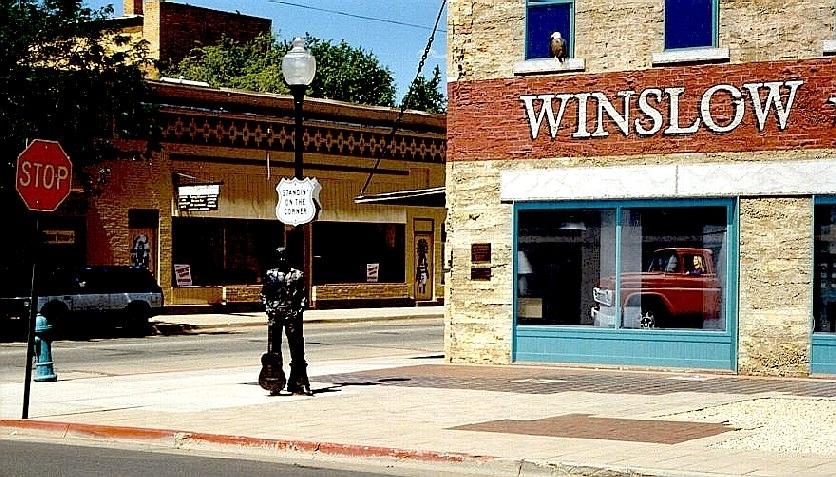

According the Frey, the second verse of "Take It Easy" refers to the time when Jackson was on one of his trips to Sedona when his car broke down in Winslow, Arizona, and he spent a long day in Winslow.

Responding to the fame of the city of Winslow erected a life-size bronze statue and mural commemorating the song, at the Standin' on the Corner Park. The statue stands near a lamp post, the male figure securing an acoustic guitar between his right hand and the shoe of his right foot. Above his head, a metal sign, crafted in the style of U.S. Route shields, displays the words "Standin' on the corner". The trompe-l'œil mural on the wall behind the statue is that of a storefront, and includes what would appear to be the reflection of a red flatbed Ford pickup truck driven by a blonde-haired woman. The second floor of the mural features an eagle perched in one window on the left and a man and woman (apparently the man on the corner and woman in the truck) embracing in another window on the right. The site has become a landmark that attracted many visitors to the town.

The Eagles performed this song soon after release in Central Park, preluding it with this verse - a possible reflection of Jackson Browne's association with country-folk American music:

"My daddy was a handsome devil

He had a chain five miles long

From every link, a heart did dangle

Of every maid he loved and wronged."

This originally is part of the song "Silver Dagger", or "Katy Dear" or "Molly Dear" or "Drowsy Sleeper" (Laws M4, Roud 2260 & 2261),and is an American folk ballad, whose origins lie possibly in Britain.

Englishman Steve Roud, the creator of the Roud Folk Song Index and an expert on folklore and superstition, observes

"A whole book could be written this song which involves its connections with other songs which involve young men at their sweethearts' windows at night, disapproving parents and silver daggers. Hugely popular with North American traditional singers, 'Drowsy Sleeper' was also collected regularly in Britain and appeared on broadsides there from at least the 1820s"

Two strands became popular in commercial Country music and Folk music recordings of the late twentieth century: the "Silver Dagger" version popularised by Joan Baez and the "Katy Dear" versions popularised by close harmony brother duets such as The Callahan Brothers, The Blue Sky Boys and The Louvin Brothers.

In "Silver Dagger", the female narrator turns away a potential suitor, as her mother has warned her to avoid the advances of men in an attempt to spare her daughter the heartbreak that she herself has endured. The 1960 recording by Joan Baez features only a few of the many verses of a version collect and published in 1907. "Katy Dear" uses the same melody but different lyrics, telling a similar story from a male perspective.

The song was recorded commercially as O! Molly Dear Go Ask Your Mother by Kelly Harrell in 1926 as Sleepy Desert by Wilmer Watts And The LoneLy Eagles in 1929 and as Wake Up You Drowsy Sleeper by The Oaks family in 1930. As Katie Dear (Silver Dagger) it was recorded by the Callahan Brothers in 1934, and as "Katie Dear" by the Blue Sky Boys in 1938. (Country music authority Bill C. Malone states that the Callahan Brothers learned traditional ballads like "Katie Dear" from their mother). In 1956 it was recorded by the Louvin Brothers. The song was part of the repertoire of the Country Gentlemen, who toured both the bluegrass and folk music circuits during the 1950s and 1960s. In the early 1960s, "Katie Dear" was recorded by folk revival musicians, including Joan Baez, and Ian & Sylvia. Today it is commonly performed and recorded by bluegrass musicians.

The disagreement of the title and some lyrics are a result of the song being handed down through the unwritten, oral tradition for several decades, where each performer would undoubtedly and sometimes unknowingly add their own nuances to the song. However, the melody and events depicted in the song are so similar that most musicologists believe that these two songs trace back to one original source.

"Silver Dagger" as sung by Joan Baez

Don't sing love songs; you'll wake my mother

She's sleeping here, right by my side

And in her right hand, a silver dagger

She says that I can't be your bride.

All men are false, says my mother

They'll tell you wicked, lovin' lies

The very next evening, they'll court another

Leave you alone to pine and sigh.

My daddy is a handsome devil

He's got a chain five miles long

And on every link a heart does dangle

Of another maid he's loved and wronged.

Go court another tender maiden

And hope that she will be your wife

For I've been warned and I've decided

To sleep alone all of my life.

The song has also been widely performed and recorded by bluegrass musicians, as many songs thought of as traditionally bluegrass songs actually trace back to what is now known as "old-time" music.

References

Silver Dagger (song). (2016, January 15). In Wikipedia, The Free Encyclopedia. Retrieved from https://en.wikipedia.org/w/index.php?title=Silver_Dagger_(song)&oldid=699929060

Take It Easy. (2016, January 29). In Wikipedia, The Free Encyclopedia. Retrieved from https://en.wikipedia.org/w/index.php?title=Take_It_Easy&oldid=702274866

The Eagles - Take It Easy Central Park (1972)

1958 Bedford 'D' truck by A J Guesdon, 2016.

Previous Collectors Corner pages:

Blacksmiths and Tinsmiths Nylon Stockings Poster Art Furphy's Water Cart Mousehole Anvil Sapphire One Armed Bandit Gould's 1840 Single and Compound Microscope Tibetan Thangka Wheel Of Life Painting Cast Iron Seats Mabel Lucie Atwell Prints The Customs of Traditional Dining by Hans and Jenny Carlborg Albert Collins Landscape Boomerang Harmonicas Drinking: 18th Century Style Part I by H&J Carlborg Drinking 18th Century Style Part II by H&J Carlborg Fleece Shears Wood Case Crank Telephone 1803 Timepeice Vintage Guitars Milestones No.38 Rolls Royce Motor Oiler Christmas Postcards Seashells McCormick-Deering Horse Drawn Mower Rope Making Machine Marilyn Monroe 1955 Calendar Stubbie Holders Hill's Hoist Akubra Hat Fowler's Bottling Kit The Bold Autographed Script Fishing Tackle Arnotts Biscuit Tins Comic Books Silver Opium Pipe Mrs Beetons Book Souvenir Teaspoons Bendigo Pottery Gianelli Figurines Key Fobs Model Aircraft-static Porcelain Slippers Wagon Wheels Rhys Williams Painting Chinese Guardian Lions Australian Halfpenny Bud Vases Rolling Stones Still Life LP Autographed WL1895 Thinking Monkey Estee Lauder Ginger Jar Reel Mowers Surf Reels Millers Car Collection Hilton Lingerie - Slips Miniature Books of Verse - A Romantic Tradition REGA Pouring Can R O Dunlop - Sailing At Itchenor Painting Morning Shadows by C Dudley Wood The Father of Santa Claus - Xmas 2012 HMS Penguin Anchor at RPAYC - Newport SS Birubi Mast at RMYC - Broken Bay Helen B Stirling Ship's Wheel at Club Palm Beach Woomeras HMSEndeavour Replica Cannon at RPAYC The Doug Crane Classic Handmade Double Blade Paddle HMS BountyWooden Ship Model Collecting Ladies - Ferdinand Von Mueller and Women Botanical Artists Australian Bark Art Chinese Ginger Jars Hand Plough and Jump Stump Plough - Australian Inventions Frank Clune Books Frederick Metters - Stoves, Windmills, Iron Monger Trinket Boxes 1933 Wormald Simplex Fire Extinguisher is Pure Brass Chapman 'Pup' Maine Engines - Chapman and Sherack The Beach Ball Figureheads Salty Wooden Personifications of Vessels Binnacle at RMYC The Australian Florin - Worth More Than 20 Cents to Collectors Weathervanes; For Those Passionate About Seeing Which Way the Wind Blows Her Majesty's Theatre 1962 Programme - Luisillo and his Spanish Dance Theatre Cooper's Sheep Shower Enamel Sign and Simpson's and Sons of Adelaide Jolly Drover Sugar Bowl and English Pottery A Means to Gaze into the Past Chief Joseph and Edward S Curtis; His Remarkable Images of Native Americans an Inestimable Record of Images and Portrait Photographs His Masters Voice, Old 78's and Australia's Love of Music Jack Spurlings 'Tamar' Picture 1923 Resch's Beer Art - A Reflection of Australiana Now Worth Thousands The Compleat Angler - Izaak Walton's Discourse Inspires Generations of Fishers Portable Ice-Boxes and Coolers How Many Claim This Invention as Theirs? Malley's and Sons Ltd. - A Munificent Australian Family Company Vintage Paddles and Gigs Nautical Memorabilia The Crinoline - a 550 Year Old Fashion B.B. King - King of the Blues Goes Home: a Timely look into Photographs and Autographs and Being Buyer Aware Deep Down Among the Coral - By Christopher Corr - A Limited Edition Print in Celebration of the seventy fifth anniversary of QANTAS Airways Old Chinese Rice Bowls for Marriage: Worth More Than You Think... Commanderie St. John: An Ancient Wine - From 1927 with Lineage to Cyprus in 1210/92 and Methods of Production to Greece in 800 B.C. Pittwater Regatta Air Race Trophies: from 1934 and 1935 and The Pilot Who Saved William Hughes Vintage Brass Mortar and Pestle