August 30 - September 5, 2020: Issue 464

Binishells In Pittwater Schools

Dr Dante Bini graduated from the University of Florence, Italy, in 1962. He was influenced by the experimental work in building with concrete and the designs of Heinz Isler, Felix Candela, Frei Otto and Buckminster Fuller. Although interested in domes as a built form, for Bini the expensive and complex formwork required was prohibitive.

In trying to resolve this, Bini began exploring the potential of inflatable formwork, or what he would term ‘Pneumoform’. His technique utilised an inflatable neoprene-coated nylon membrane overlaid with a network of steel springs and reinforcing bars. A thin layer of concrete was then poured over the membrane. In a process that took roughly one to three hours the membrane was then inflated, the entire mass of wet concrete, springs and reinforcement rising to the desired form. The Pneumoform used readily available materials, reduced waste, eliminated costly formwork and large site teams, and dramatically sped up the construction process.

Bini successfully demonstrated his technique in 1965 in Crespellano, Italy, with a 12-metre diameter, hemispherical concrete shell structure. The patented automated system was licensed across the globe with Binishells rapidly constructed in Brazil, Cuba, Saudi Arabia and the UK.

In 1971 the Department of Public Works New South Wales was seeking a fast and cost-effective construction technique to add desperately needed multipurpose centres, gymnasiums, libraries and other buildings across New South Wales schools. Ian Thomson from the NSW Government Architect’s Office, travelled to Italy to meet Bini and explore the system. Clearly impressed, the Department of Public Works engaged Bini as an architectural consultant to design, direct and train its staff in all aspects of constructing the domes. Bini’s considerable energy and charm burst on to the Sydney architecture scene, and he remained in Sydney for six years as a prominent figure advocating, developing new construction techniques, and lecturing at the University of Sydney.

In 1974, the Department of Public Works New South Wales began a comprehensive program of new school buildings using a radical concrete dome technology.

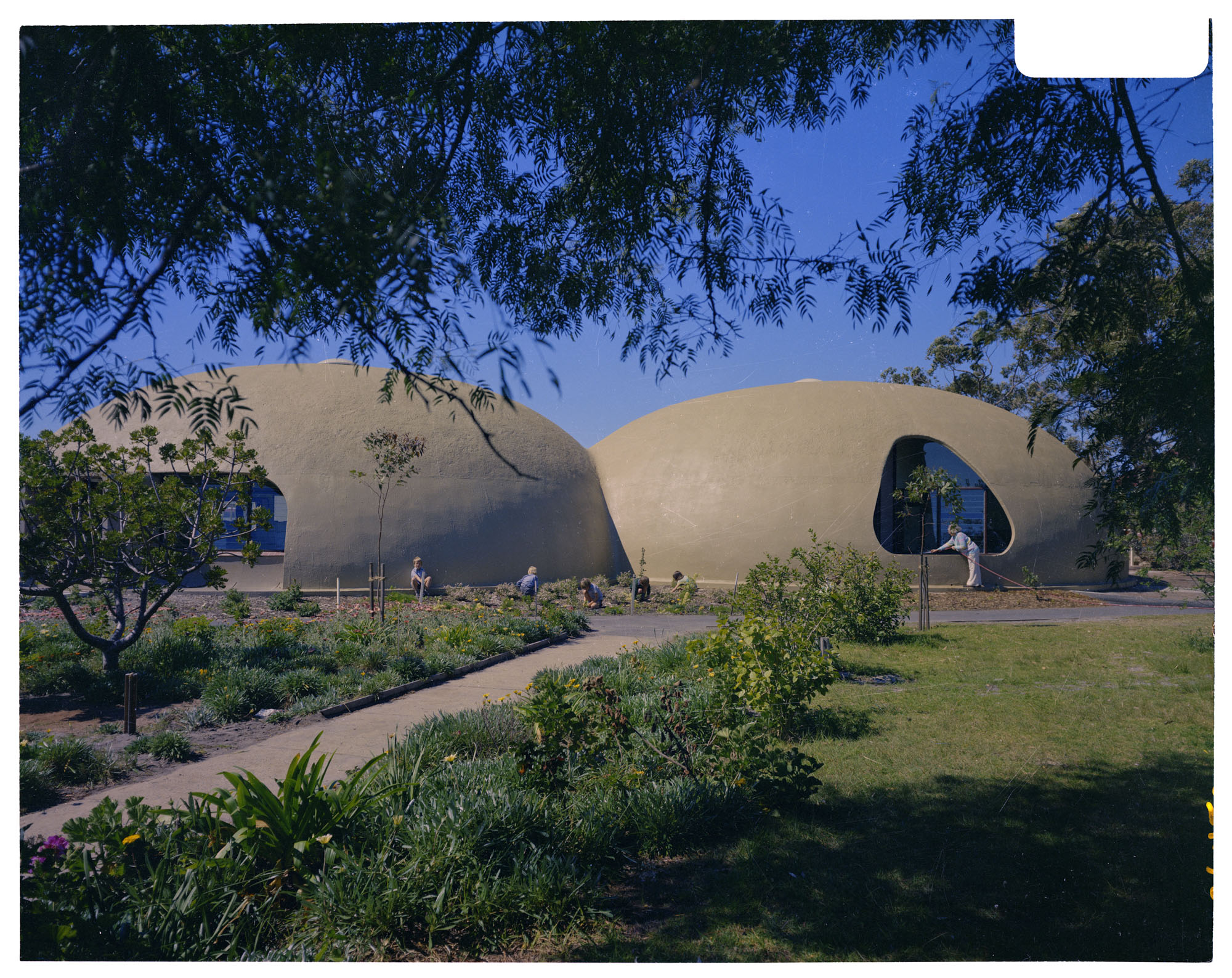

The first school project, Narrabeen North Public School library was a showpiece of the method’s potential. Dr Bini subsequently installed his inflatable, concrete clad ‘Binishells’ to provide multi-function facilities in schools across the state but the three-dome complex was one of Bini’s career favourites.

Dante Bini reflected on this his first Binishell project for NSW Schools;

'This should be a showcase project, I thought, as I conceived a spherical support for an asymmetrical opening of two intersecting domes. In a symbolic piece of design, the first two Binishells represented an opening shell that offered young students the pearls of knowledge contained in this new library.' (Heritage Inventory Form, Anne Warr and Jane Green. May 2019)

The North Narrabeen Public School binishell structure comprises 3 multi-use Binishell buildings, two of which interconnected domes designed as a library with the third being an administration office for the school. The binishells are 18 metres in diameter and are constructed of steel and concrete with glass windows. An internal steel reinforcing frame was installed after the original construction. (National Trust nomination September 2018)

The buildings were erected and opened in 1974 and were the first Binishells to be constructed by the Building Construction and Maintenance Branch of the Public Works Department. The library entrance incorporates a large concrete (?) ball under the eve evoking a pearl in a shell. The library reception desk is/was located at the centre of the conjunction of the two domes and has a mezzanine level used for reading recovery activities.The administration dome has facility for staff offices, a sick room, printing room, interview room storeroom and toilets. The first floor contained a large common staff room. This binishell is currently the before and after school care centre. (NSW Public Works Advisory, NSW Department of Education Binishell Strategy August 2018)

The domes are situated in a central position in the school grounds and are surrounded by a grove of mature native trees and landscaped mounds of lawn, a native landscape setting popular in the 1970s.(NSW Public Works Advisory, NSW Department of Education Binishell Strategy August 2018) [4.]

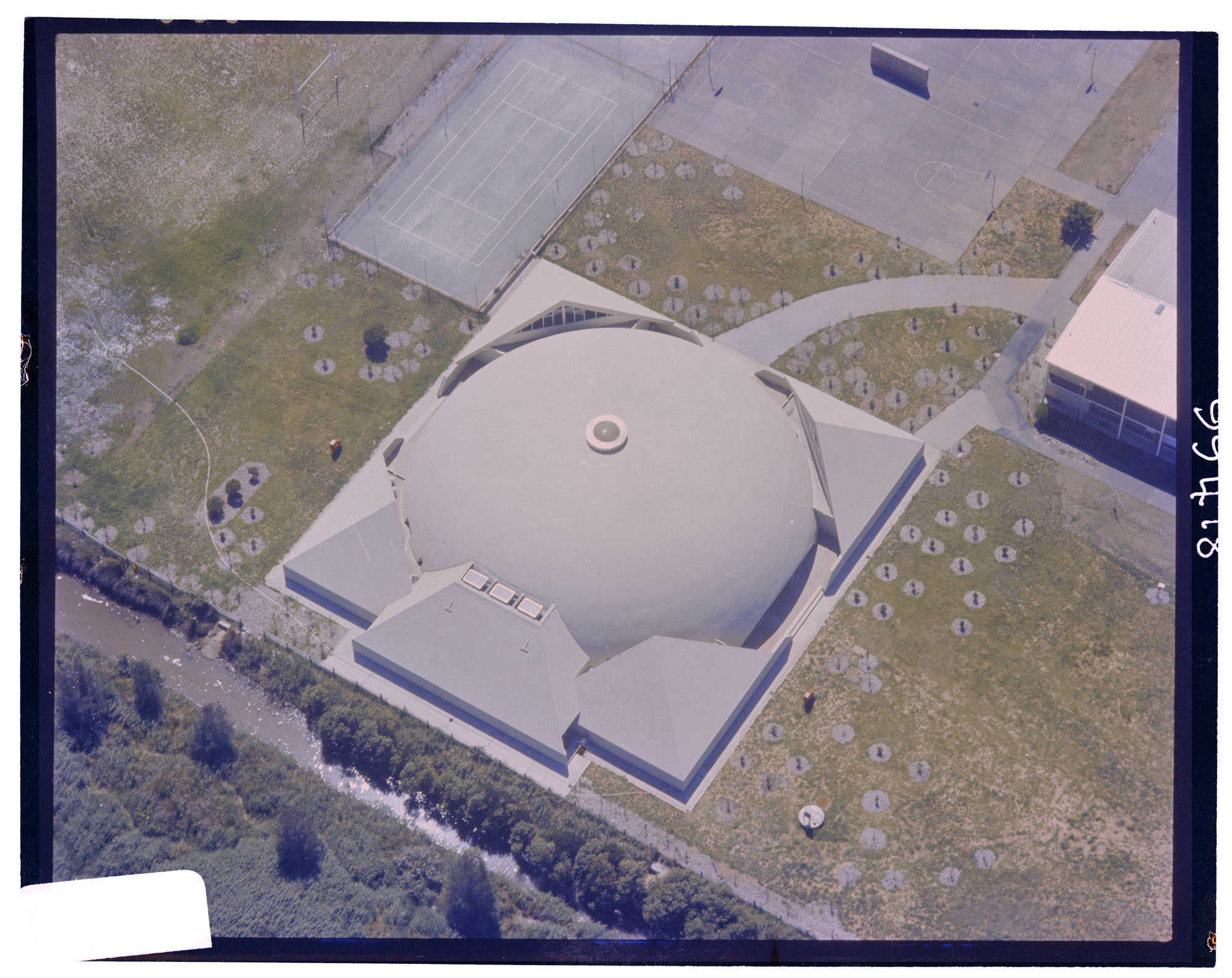

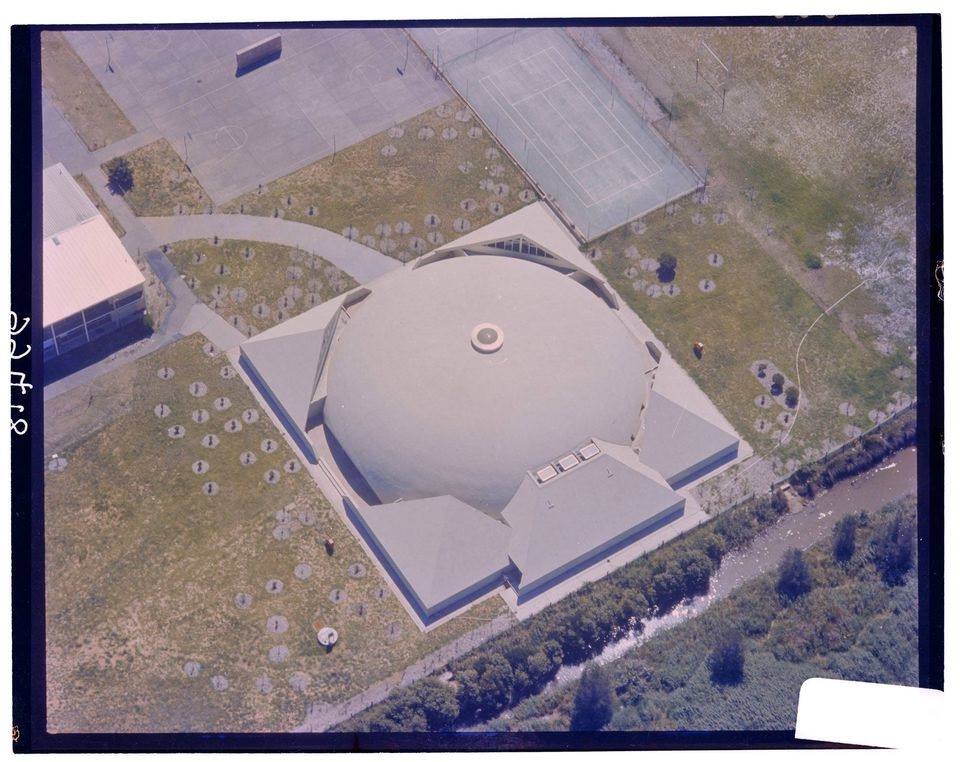

Binishells are reinforced concrete thin-shell structures that are lifted and shaped by air pressure. Between 1974 until 1978 the Department of Education constructed eight Binishells or shell complexes. The program included 18-metre diameter shells or shell complexes, generally used as libraries, and 36-metre diameter multipurpose centres, often used as gymnasiums.

Improvements to the original system included greater architectural flexibility, compliance to international building codes, simplification of the construction process and integration of latest material and passive heating/cooling technologies. Bini’s legacy is considerable with 1,500 Binishells constructed in 23 countries.

Photos; 1: Binishells, North Narrabeen Public School - one of exterior, one of interior. Photos dated 10/9/75, the first Binishell project erected for NSW school.

2: Binishell, Pittwater High School - Aerial photograph of Binishell at Pittwater High School, Pittwater - taken in February 1978.

The Pittwater High School dome collapsed on August 4th 1986. It had been preceded by the collapse of a dome at Fairvale High School in Fairfield west. The failure in the 36 metre diameter Binishell at Pittwater High School was later found to be due to errors in the curing process. As a result of the failures the 36 meter diameter Binishells throughout the state were also retrofitted with an internal steel reinforcing structure.

However the day of the binishell in Australian schools ended with this second Pittwater High School collapse - students had been in the structure shortly beforehand and a cleaner was lucky to get out uninjured as the structure collapsed. Parents around the state did not want their children exposed to such danger and schools were already planning their demolition and substitution with more conventional buildings.

Pittwater HS Binishell flipped photo to show how was on site - courtesy Dave Murray

Other Building companies in Australia also undertook to build binishells - A V Jennings for example, now known as Jennings Industries.

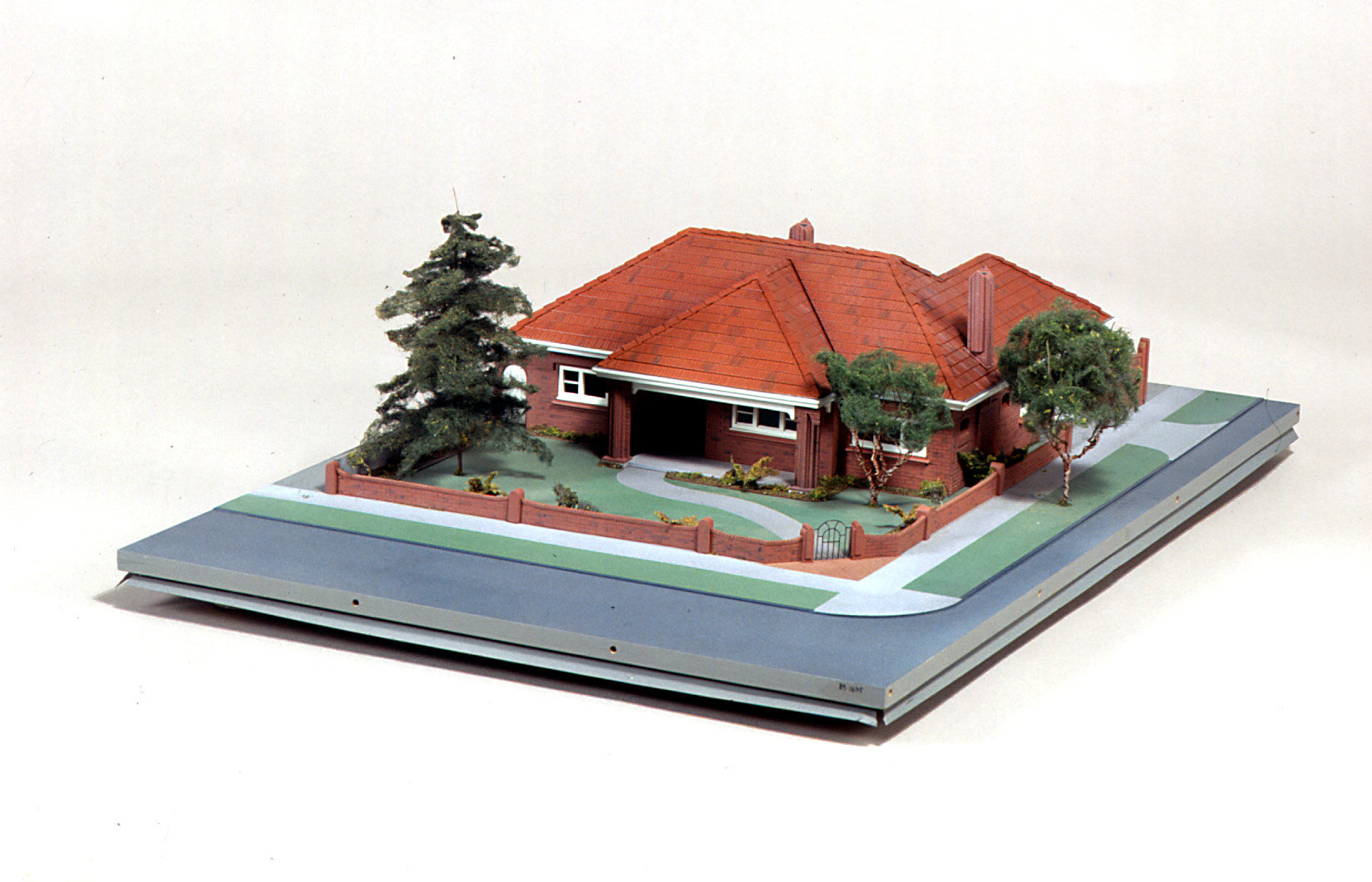

In 1932, 35 year old Albert Victor Jennings was an experienced real estate agent working at his brother-in-law's agency in the growing suburb of Glenhuntly in Victoria. At that time, there were no new homes to sell as construction had stopped due to the Depression and many building industry workers were without jobs. In an effort to create work for himself, Jennings mortgaged his own Glenhuntly home and contents and raised a £700 overdraft to start his own homebuilding business. This was enough to pay wages by not enough to finance the building of homes, so Jennings decided to pre-sell homes from architect prepared plans instead of the traditional builder's approach of building and then selling. The decision proved to be a corner stone of Jennings' later sales policies.

Architectural Model - A.V. Jennings House. Source: Museums Victoria. Copyright Museums Victoria / CC BY (Licensed as Attribution 4.0 International)

Working with architect Edgar Gurney and builder William Vine, A.V. Jennings established a company that continues to build houses across Australia. Mr. Jenning's house building philosophy was premised on a tradition of solidity, homeliness and value for money and exercised his belief that good family homes helped create happy and good Australian citizens. In 1969 he was knighted and the following year he was awarded the AIB medal although to many he would remain 'Bert'.

Jennings was responsible for other innovative projects in Australia, the Wrest Point Hotel Casino, Australia's first legal casino, opened in the suburb of Sandy Bay in Hobart, Tasmania, on February 10th 1973, was a Jennings project. The author recalls going there every weekend during construction time so her father, then state manager in Tasmania for Jennings, could inspect that weeks' works without anyone else on site to tell him how well they had done that week - he liked to look for himself!

One of the highlights of these Sunday family weekend outings was calling into nearby Magnet Court afterwards (called this due to its traditional magnet shape; 'U'). Here dad bought us hot donuts, then a novel sweet in Australia, and a stick of Blackpool rock candy; which would take the rest of the day to eat. These were bright pink or red on the outside and white inside with writing around the centre that could become bigger as you worked your way through it.

One of the highlights of these Sunday family weekend outings was calling into nearby Magnet Court afterwards (called this due to its traditional magnet shape; 'U'). Here dad bought us hot donuts, then a novel sweet in Australia, and a stick of Blackpool rock candy; which would take the rest of the day to eat. These were bright pink or red on the outside and white inside with writing around the centre that could become bigger as you worked your way through it.

Blackpool is a large town and seaside resort on the Lancashire coast in North West England which became popular when it started to be fashionable to travel to the coast in the summer to improve well-being by getting in saltwater, from around the early 1800's - and very popular by the 1850's.

The Wrest Point Hotel Casino was designed by Sir Roy Grounds, (18 December 1905 – 2 March 1981) one of Australia's leading architects of the modern movement. The 18-story octagonal tower, at 64 metres, the building was, and still remains, the tallest building in Hobart, and includes a revolving restaurant at the top of the tower. It was heritage listed in 2017.

Wrest Point Casino at night - photo by J J Harrison

In the late 1970s, Jennings Industries Limited negotiated a licensing agreement with Dr Dante Bini and the result was fifteen Binishells built across New South Wales high schools, twelve of which remain. Mr. Bini and Jennings also beat the record for the largest Binishell complex in the world, with the construction, outside of Brisbane of the Space City Shopping Centre, unfortunately demolished (Jennings Industries 1978).

Mr Hindmarsh New ACT manager of Jennings

The new divisional manager for Jennings Construction Group in the ACT is Mr John Hindmarsh. The former manager, Mr Peter Rogers, has been transferred to Melbourne as manager of the Binishell division of the Jennings Construction Group. Mr Rogers also was the vice president (commercial) of the Master Builders Association of the ACT and a member of the MBA council. New ACT manager of Jennings (1976, December 6). The Canberra Times (ACT : 1926 - 1995), p. 10. Retrieved from http://nla.gov.au/nla.news-article131799555

ENERGY AND RESOURCES

Building, construction infrastructure

By J. M. JORGENSEN Federal Executive Director, Master Builders' Federation of Australia

The building and construction industry provides the infrastructure for the development of Australian resources and industry: as such, construction absorbs a substantial proportion of the national capital investment estimated at 8 per cent of Gross Domestic Product.

The industry produces the dwellings, commercial projects, industrial complexes, the port facilities, roads, rail links, power generation and transmission facilities, water supply systems, airports, harbours, docking facilities, mining townships, necessary for that national development.

It represents a $12 billion industry, directly employs some 350,000 people or 7 per cent of the civilian workforce.

It also provides employment for a vast number of others who produce equipment, materials and services associated with the construction phase and other people employed in the provision of plant, equipment, furnishing, fittings, in the use and occupation of the structures.

There are very large organisations in the construction industry but in aggregate the work is predominantly carried out by medium and small-sized unincorporated interprises dominated in numbers by small self-employed contract units.

The construction industry components of Gross Domestic Product at factor cost show this breakdown as: Company 7.9 per cent; public enterprises 0.6 per cent; unincorporated enterprises 23.0 per cent; wage, salaries and supplements 68.5 per cent.

The building industry is constantly innovating and over the years has seen a large number of new techniques, methods, and materials introduced. In general these changes have been along the line of gradual evolution rather than an impact or sudden type of change as the industry, because of its dispersion and variety of projects, is largely labour oriented with only a small amount of capital in relation to the value of work done per annum.

What must be remembered is that across the world building and construction has always been and will continue as one of the basic service industries and new technologies are universal. Australian manufactured cranes were used for the creation of the New York Trade Centre while innovation from Italy can be seen in Australia in the new Binishells projects constructed by Jennings Industries.

It is a highly creative and innovative institution, by its nature highly competitive, and because of the structure of contract units, highly efficient. By innovation more efficient organisation and transfers of labour from on-site to offsite production, the size of the on-site labour force has been steadily reducing with no subsequent reduction in the value of output.

The quest for low-energy consumption buildings is likewise universal with Canada and the United States heavily involved in experimental programs, while in Australia the CSIRO division of building research and mechanical engineering have initiated a low-energy consumption house project in Victoria.

Writing in the Chartered Builder, the journal of the Australian Institute of Building, N. J. Wooldridge BSc, outlined some of the major objectives of the Australian research project. Clearly, energy usage rates will not continue to increase indefinitely because population growth shows signs of levelling out while market saturation of appliances, together with emerging social responsibilities should ensure a modification of the demand pattern.

This emerging social responsibility is another way of describing the community's perception of the need for conservation.

Requirements for thermal comfort, hot water, cooking, lighting and operation of other appliances in our building account for over 20 per cent of Australia's primary energy consumption. Almost two-thirds of the energy is used in domestic building: the remainder is used in commercial and institutional premises.

In the area of commercial and industrial structures, the Binishells process developed by Jennings Industries for the Australian market represents a significant breakthrough in construction technology. For thousands of years the dome had been recogised as one of the most efficient structures ever developed, while at the same time known to be one of the most difficult and costly to build.

Now with the Binishells process, of pneumatically inflating concrete, the construction of concrete domes is possible with a speed and economy that surpasses other conventional structures of equivalent size and during the past 12 years more than 500 Binishells have been built around the world, some as shopping centres, sports facilities, schools, industrial complexes and a multitude of other uses.

Recent fuel shortages have demonstrated the immediacy of the problem of dependence on relatively low-cost petroleum products. The longer-term problems require a more urgent response because of the time lags in the design, development, conceptual acceptance and production process. REVIEW OF THE NATION 1979 ENERGY AND RESOURCES Building, construction infrastructure (1979, July 23). The Canberra Times (ACT : 1926 - 1995), p. 19. Retrieved from http://nla.gov.au/nla.news-article110569501

Australians continue to be innovative designers and builders of great school buildings and homes, with many of those who have created these places for people living locally. The home called 'Kumale' designed by another brilliant Australian Architect, Peter Muller, and built for Mervyn Richardson, inventor of the Victa lawnmower, has round concrete features as well.

The Careel Bay Richardson weekender, 'Kumale' - photo by Robyn McWilliam, 2012

The tradition for being innovative and doing it better persists here in Pittwater and around Australia. You can visit the article Pittwater Online ran a few weeks back to see some of these new local homes, many responding to the environment they are a part of, many of these from the minds of local Designers and Architects and realised by local Construction companies.

References:

- Building With Air, Dante Bini, 2013, Butler Tanner Denis, UK, p.13

- NSW Department of Public Works publication Construction of Binishell Reinforced Concrete Domes, NSW, Australia, 1978, p.7

- Binishell Collection (Department of Education) - Retrieved from: HERE

- The Binishell Collection (Department of Education) Draft for consideration - NSW Office of Environment and Heritage, retrieved from https://www.environment.nsw.gov.au/heritageapp/ViewHeritageItemDetails.aspx?ID=5066940

- Alberto Pugnale and Alberto Bologna. Dante Bini’s “New Architectural Formulae”: Construction, Collapse and Demolition of Binishells in Australia 1974-2015. SAHANZ 2015 Conference Proceedings. Proceedings of the Society of Architectural Historians Australia and New Zealand, Vol. 32, 2015.

- Willis, E. (2009) A.V. Jennings, Home Builder in Museums Victoria Collections https://collections.museumsvictoria.com.au/articles/1249

- Pugnale, A., Bologna, A. Dante Bini’s Form-Resistant Binishells. Nexus Netw J 19, 681–699 (2017). https://doi.org/10.1007/s00004-016-0323-7

- TROVE - National Library of Australia

- Images courtesy State Library of NSW - Government Printing Office. GPO 3 - 37236, and NSW Records.