Decades ago my grandmother would turn fresh cream in a wooden milk churn in the farmhouse kitchen, later at night, when it was cooler, pausing to drain off the liquid. Then she would turn out the mass of butter and knead some salt into one portion and leave the other without before using butter pats to shape the butter into the size of quarter pound blocks.

Earlier in the day a Milk Separator had been used to divide the cream from the just brought in milk, and this too was watched, with curious eyes. While her hands worked stories of days past would be shared - seasons which brought in abundant crops of blackberries, apricots, gooseberries, peaches or greengages, that would be bottled or turned into jam.

In the morning that butter, now cooled in the pantry, would be spread on thick slabs of bread or toast and topped with those homemade jams or just eaten as is - and the taste - beyond anything you can buy as the fields those cows ate from were a deep verdant green from deep rich soil and that makes for very fine butter.

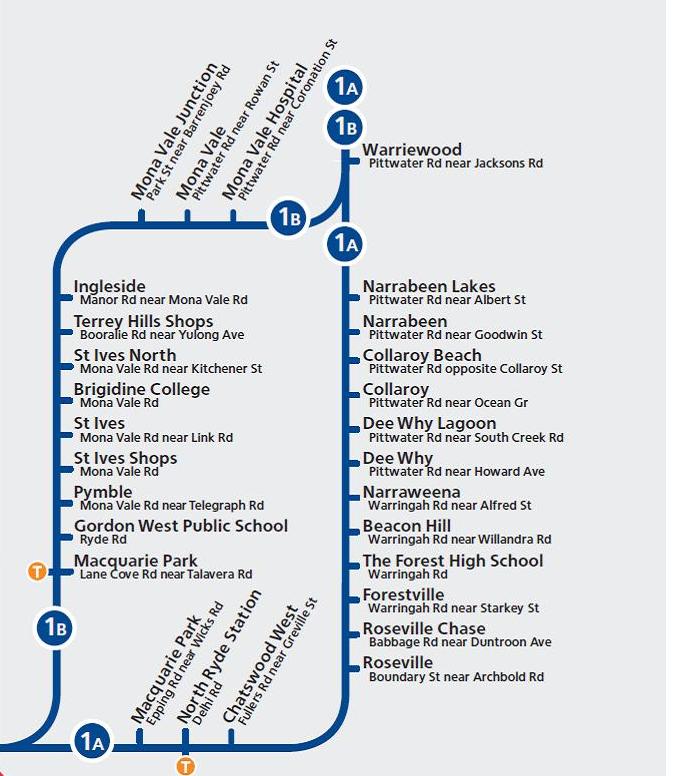

With the

Sydney Royal Easter Show (23 March - 3 April 2018) offering you a chance to experience the

Dairy Farmers Working Day, admittedly NOT with the waters of the Derwent River chugging past as background music, or with the lowing of a cow drifting in from the top paddock, we aim to arm you with some knowledge to tempt you to look into where all your food comes from and in doing so prove what I've said for decades by now - 'you can take the girl out of the country, but you can't take the country out of the girl'.

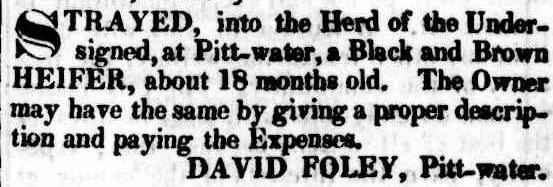

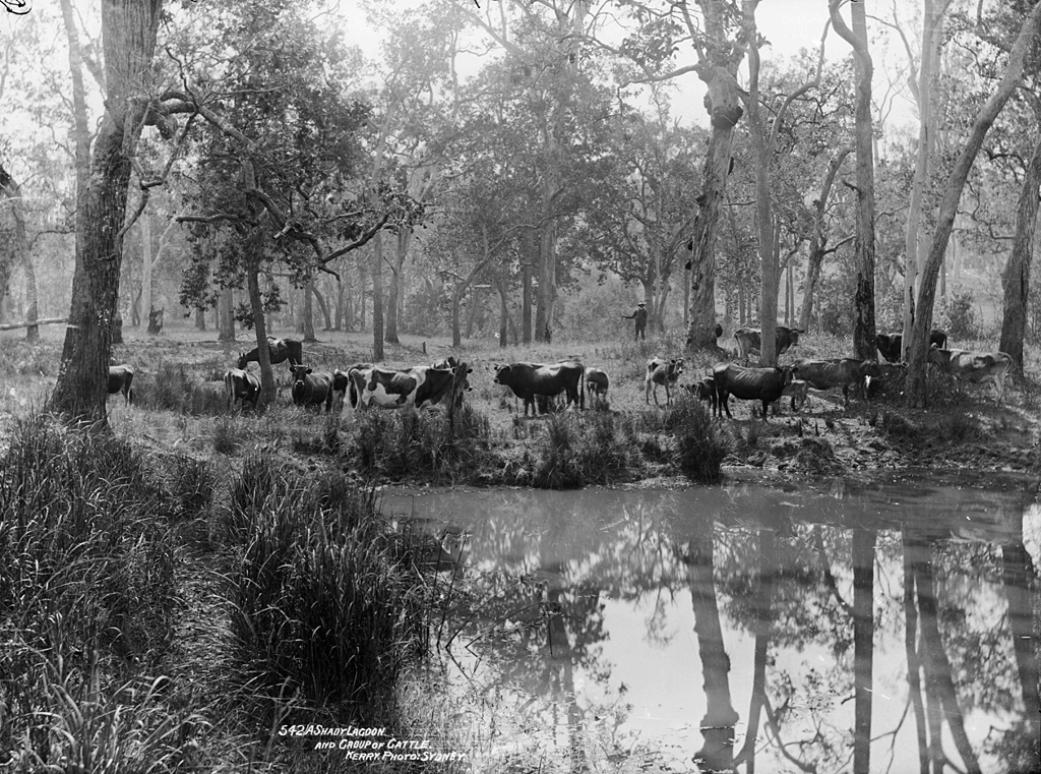

A milk separator is a centrifugal device that separates milk into cream and skimmed milk. Separation was commonly performed on farms in the past. Most farmers milked a few cows, usually by hand, and separated milk. Some of the skimmed milk was consumed while the rest was used to feed calves and pigs. Enough cream was saved to make butter, and the excess was sold.

Today these great old machines are still in use by smaller operators while others collect them simply because they like all things mechanical and they're attractive in a metallic sculptural way.

"Lister RS9" Cream Separator- found on Gumtree

In excellent Working condition comes complete with the original "Oil Can" Milk Sieve and The original Operating Manual

Before the advent of centrifugal separators, separation was performed by letting milk sit in a container until the cream floated to the top and could be skimmed off by hand. When spun, the heavier milk is pulled outward against the walls of the separator and the cream, which is lighter, collects in the middle. The cream and milk then flow out of separate spouts.

The centrifugal separator was first manufactured by Swedish Engineer and Inventor Gustaf de Laval (9 May 1845 – 2 February 1913) , making it possible to separate cream from milk faster and more easily, without having to let the milk sit for a time, and risk it turning sour. Possibly because Gustaf de Laval manufactured the first cream separators, many people credit the invention to him despite many patents appearing before his, all of them labelled as 'improvements'.

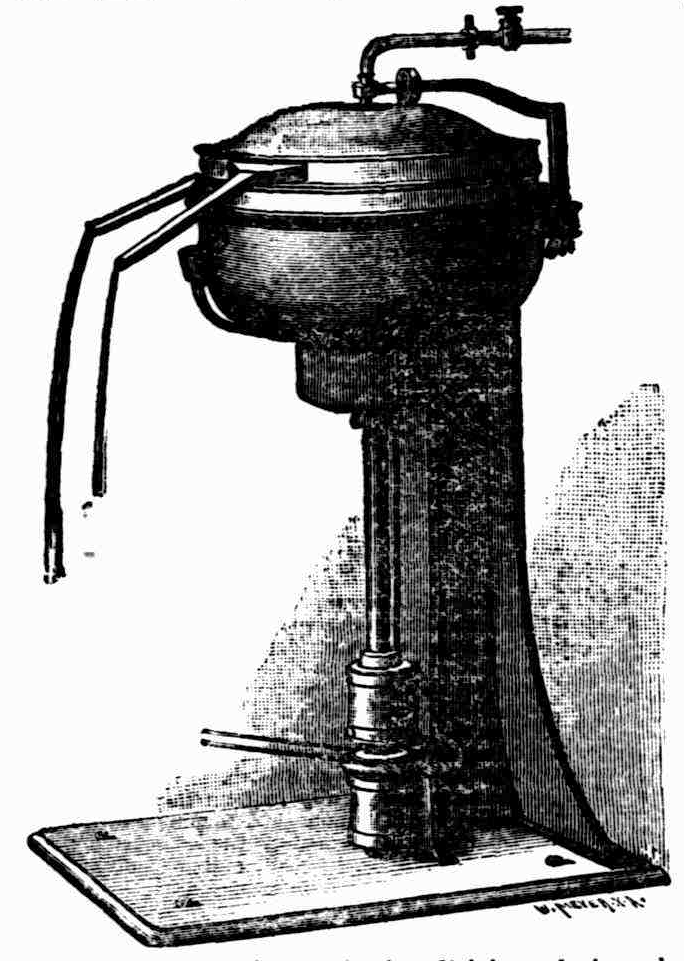

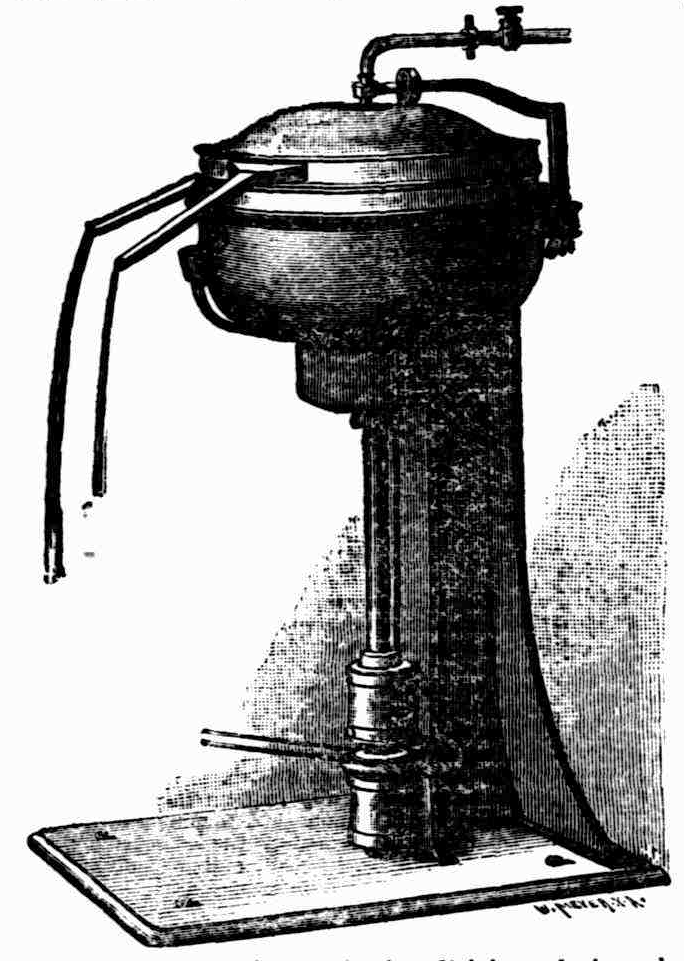

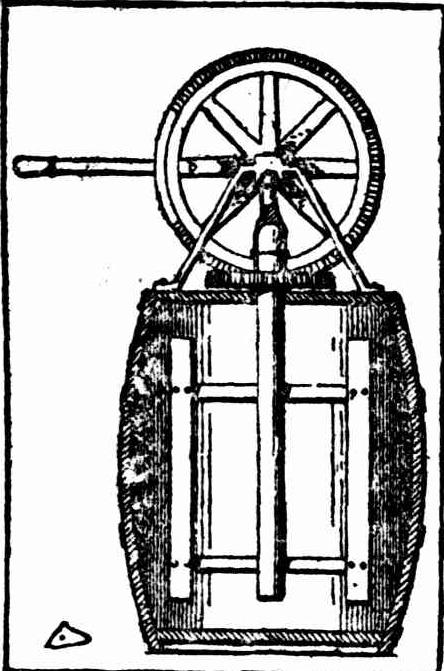

THE DeLAVAL CREAM SEPARATOR.

There is no subject of greater interest to the dairyman than how to separate the cream from the milk. Upon this decision often depends the question of profit or loss in the dairy. In any system of creaming milk the first requisite is a thorough separation of the cream and milk, but at the same time to preserve the quality of the cream. The old system of shallow pans was neither uniform or complete, in its results, while the time required to make the separation always imperilled the quality of the cream and butter. These risks were to some extent removed, and the results improved upon by the introduction of the ice method of setting. Improvements having once begun it was evident that some better system must take the place of the costly and clumsy method, of setting milk in ice water.

Mechanical genius has now, it is claimed, overcome the last obstacle to perfectly creaming the milk, greatly economising both time and space, removing all risks, and doing the work with a speed and precision such as the business of these days demands in every department. The DeLaval Cream Separator is a machine for effecting the rapid and complete separation of the cream from the milk by application of centrifugal power. The milk as it comes from the cow is placed in a milk can, and then delivered by means of an ordinary tapinto themachine, as shown in the engraving. The rotating vessel of the machine runs at a velocity of 7,000 revolutions per minute. As soon as the fresh milk enters the rotating vessel an instantaneous separation takes place, the skim milk being discharged out of the lower outlet tripe, and the cream is discharged out of the upper outlet pipe. The machine is adapted to either horse or steam power, and requires but the power of one horse to work it It is adapted either to the dairy of 20 cows or to that of 100.

This separator has completely revolutionised the method of dairying on the Continent of Europe, and is adopted by the best butter-makers in America. We are informed that 3, 500 machines have been sold up to date. It is also coming largely into use in the adjoining colonies, whereas advantages over ordinary methods are much more apparent than in colder climates.

In New South Wales twenty-five separators are now in use, and the farmer can by using this separator rely upon a better and uniform quality and a larger quantity. In the Sydney market, we are informed, the separator butter commands a higher figure per pound. We witnessed a trial of this separator some time since at the machinery warehouse of the agents, Messrs. Harrold Brothers, under the auspices of the Agricultural Society, when twenty-one gallons of fresh milk were put through the machine in the space of twenty minutes, with a result of twenty-two and a half pounds of excellent cream. The skim milk on being analysed was found to contain only quarter per cent, of fat, thus showing the complete action of the machine. Messrs. Harrold Brothers lnform us the price of the separator, with necessary intermediate gear, is £50, and they will be pleased to afford any further particulars on application to them.

A butter churn is a device used to convert cream into butter. This is done through a mechanical process, frequently via a pole inserted through the lid of the churn, or via a crank used to turn a rotating device inside the churn. Evidence for the use of butter dates back as early as 2000 BC, and there is mention of it in biblical works. The butter churn itself may have existed as early as the 6th century AD, as can be seen by what appears to be a churn lid dating from that era.

In the European tradition, the butter churn was primarily a device used by women, and the churning of butter was an essential responsibility along with other household chores. In earlier traditions of butter making, nomadic cultures placed milk in skin bags and produced butter either by shaking the bag manually, or possibly by attaching the bag to a pack animal, and producing butter simply through the movement of the animal. Some theorists believe this is how the butter creation process was discovered. Some cultures still use a process similar to this, whereby a bag is filled with milk, tied to a stick, and vigorously shaken.

The word “butter” is believed to be derived from the Greek word bou-tyron, the approximate meaning of which is “cow cheese”. However, some believe the word came from the Scythian culture, as the ancient Greeks tended to herd sheep and goats, whose milk is not as good for butter making as that of cows, which the Scythians primarily herded.

The word "churn" is from the Old English ċyrin, to churn. This may be derived from the Old English cyrnel, "kernel," due to the appearance of butter grains after milk has been churned.

The butter churn gave its name to the milk churn, early examples of which were based on butter churns. The milk churn is not, however, used for the act of churning, but rather to transport milk. These too are collected today, some are put to good use to make butter and cheese while others provide pleasing memories to those who want them or provide an interesting attractive addition to what is collected.

Some early Australian reports and examples;

AIR CHURN.

The Bishop of Derry has invented an atmospheric churn. Instead of the present unscientific mode of making butter by churning, his Lordship accomplishes this measure by the simpler manner of forcing a full current of atmospheric air through the cream, by means of an exceeding well-devised forcing pump. The air passes through a glass tube connected with the air-pump, descending nearly to the bottom of the churn. The churn is of tin, and it fits into another tin cylinder provided with a funnel and stop-cock, so as to heat the cream to the necessary temperature. The pump is worked by means of a wind), which i3 not so laborious as the usual churn. Independently of the happy application of science to this important department of domestic economy, in a practical point of view it is extremely valuable. The milk is net moved by a dasher, as in the common churn ; but the oxygen of the atmosphere is brought into close contact with the cream, so as to effect a full combination of the butyraceous part, and to convert it all into butter. On one occasion the churning was carried on for the space of one hour and forty-five minutes, and eleven gallons of cream produced twenty pounds of butter. — Globe. AIR CHURN. (

1846, May 30).

The Cornwall Chronicle (Launceston, Tas. : 1835 - 1880), p. 409. Retrieved from

http://nla.gov.au/nla.news-article65941704

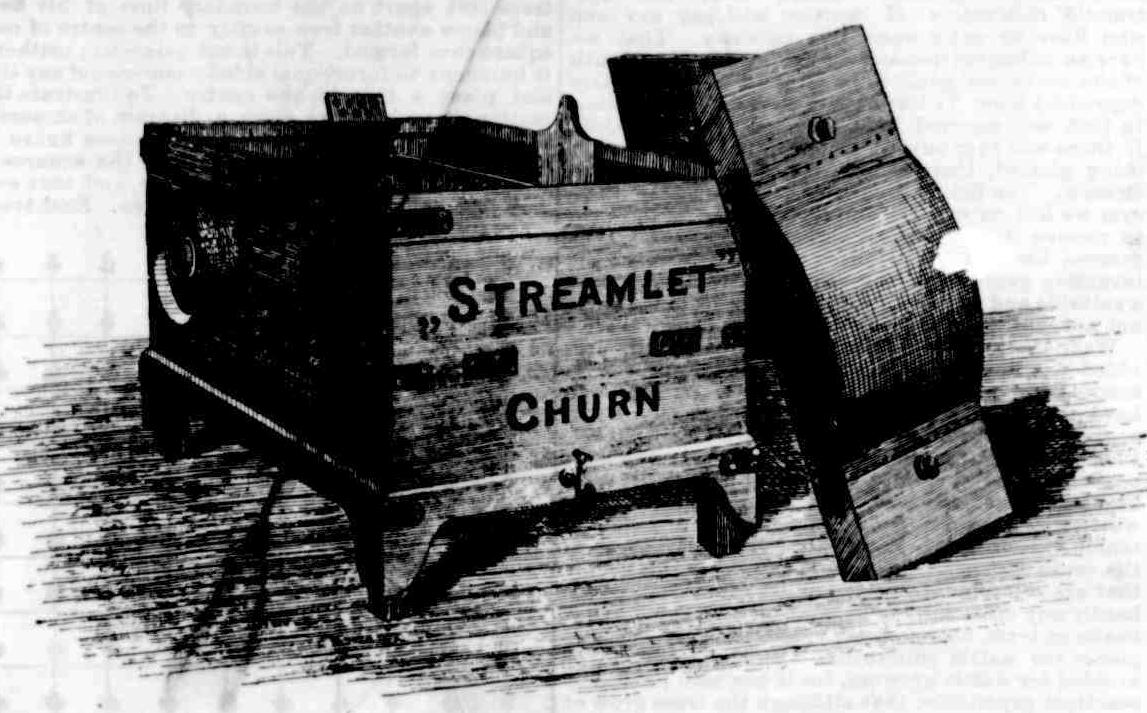

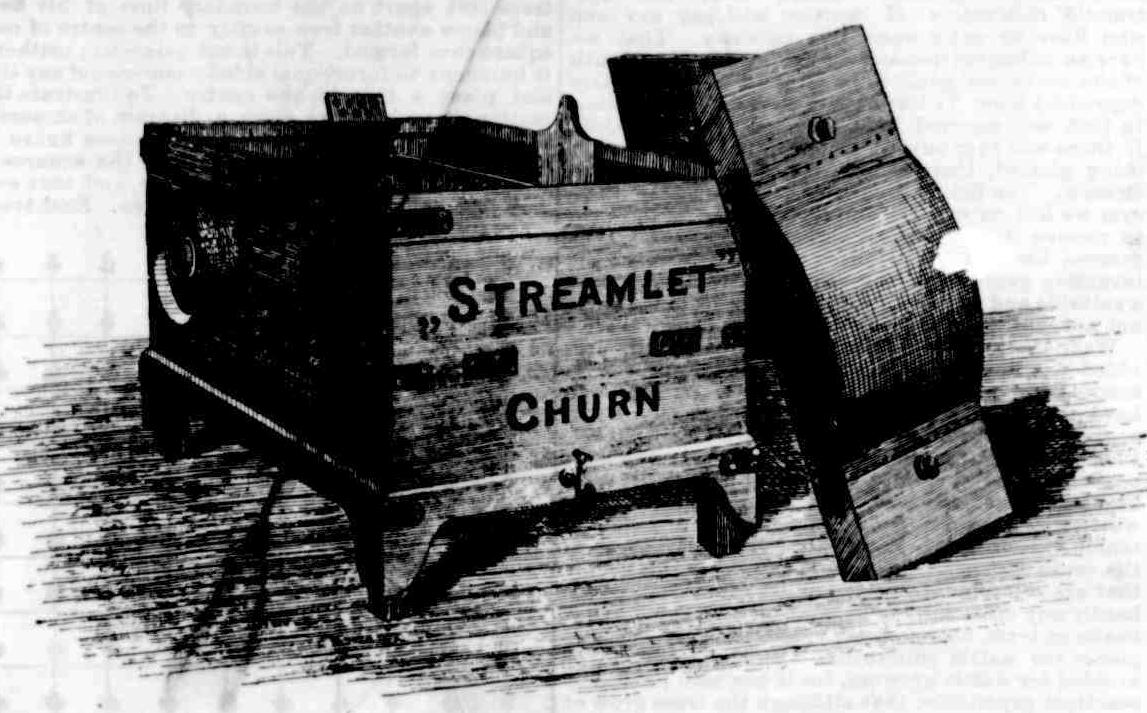

Streamlet Churn.

This ingenious churn, of which we give an illustration this week, is a thoroughly practical advance in the art of butter manufacture. These churns are built to any size convenient for handling by steam or hand power. The one under consideration has a capacity of churning 100 gal of cream. The principle and construction of this admirable churn are as follows : Built of well-seasoned kauri pine. Dimensions, 4ft x 2ft 9in by 2ft deep. The body is divided into two compartments by a strong inch board. At each end of this board there is an opening of about 6in ; one opening may to shut by a slide perforated at tho bottom. The object of the division and openings is to cause the cream to flow round in a circle, every particle of it in its turn being operated upon by the " dash boards." The "dash hoards " are six in number, fitted alternately on a double wheel, so to speak. One set of these is perforated by |in augur holes ; the other set is composed of bar frames, both being strongly fitted in brackets. It will thus be seen that the cream in process of churning is kept in a constant state of extreme agitation, and that it is all equally churned.

The Streamlet Churn. (See letterpress on this page.)

When tho butter begins to granulate, this sideboard, already referred to, is pushed down ; this causes the retention and accumulation of the butter in one corner ; removing the lid of this division the butter can be taken from the churn as work progresses, without any stoppage to machinery. This in itself may seem a small matter, hut it is in fact a great consideration, not only as a saving of time, but as regards the quantity of butter extracted from the cream. For instance, when the morning and evening's cream is placed in tho churn, as everybody knows, it is then not of equal ripeness, and consequently requires more or less caution to produce the butter. Thus, while in the old churns the butter must be removed as soon as it comes, leaving still a portion of the unchurned cream in the churn, every dairyman will at once see the immense advantage of this improvement. The buttermilk is allowed to run off through a large tap at one end of the churn. The principle of this churn is without doubt a splendid one, and should at once commend itself to the numerous butter factories and dairymen generally. The points of advantage claimed, simply stated, are as follow :

1. Simplicity of working ; any novice can use it.

2. No supervision required. The " grain" of the butter cannot be spoilt, churn as long as you will.

3. The fact of the butter remaining collected in one corner of the churn immediately preserves the grain.

4. The percentage of butter extracted from the cream is of necessity greater than with other churns.

5. Creams of different ages can be churned together with an equally satisfactory production of butter.

6. Can be cleansed easily. Butter milk is run off by means of a large tap at one end of the churn. Dash boards are also easy of removal.

This churn has been patented in all the colonies, and has given intense satisfaction wherever used. The prices quoted are very reasonable. Testimonials and all particulars may be had at the South Coast and West Camden Co-operative Co., limited, Sussex and Liverpool streets, Sydney. Inspection will at once convince dairymen of the improved utility and saving of time with a churn of this kind. Streamlet Churn. (

1890, May 31).

Australian Town and Country Journal (Sydney, NSW : 1870 - 1907), p. 22. Retrieved from

http://nla.gov.au/nla.news-article71112117

New Butter Churn.

A new butter churn, designed by Mr W. B. Walten, of Dunedin, on the pneumatic principle, was exhibited on 6th inst. at the premises of the Fresh Food and Frozen Storage Company. The application of air propulsion to churning is well-known, but the invention is the first in which the process is mainly carried out by the creation of a vacuum. The churn is a large cylinder shaped vessel of strong tin, and when fully charged with cream exhibits a email vacant [pace at the top which is connected with a steam pipe. Near the bottom of the churn there is a connection with a coil of piping which stands in a separate cistern about 1ft distant. By turning on the steam a vacuum is created in the upper part of the churn, and the air from the lower pipe is drawn upward, in this way agitating the cream or milk, and producing the full process of churning. The churn may also be worked by water or air power, but steam is tho most suitable, ns it enables the temperature of the air drawn through the spiral pipe to be accurately regulated by means of a thermometer. It is claimed that the passage of air through the cream purifies it to an extent which cannot be attained by any other method. An additional cistern is fixed to the churn to enable the washing of the butter to be expeditiously carried out by application of the same power which is used for the churning. — Melbourne Leader.

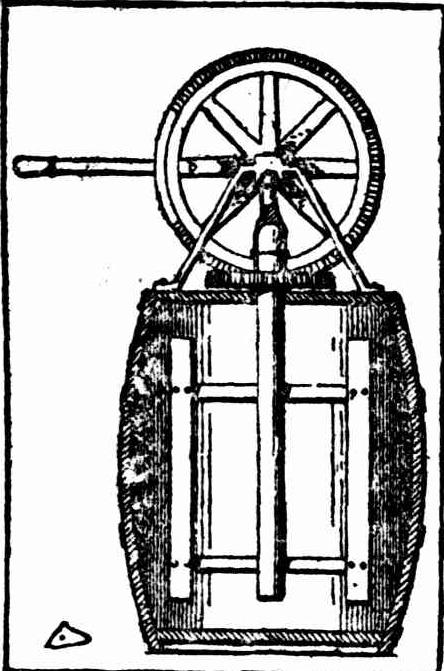

Churn Butter Quickly.

A Kansas farmer is the inventor of the churn herewith shown. The body of the churn has a cover supporting a movable frame, to which the operating mechanism Is secured. The mechanism Consists of a gear wheel formed integral with an axle and shaft, which extend down into the body of the churn to within an Inch of the bottom. Mounted rigidly on the shaft are hori-. zontal crossbars, carrying the vertical paddles or dashers. Supported by the frame secured to the cover is a vertical gear wheel, which meshes with the horizontal gear wheel, the former being operated by a handle. After the creami has been placed In the churn the handle is moved from right to left, which imparts motion to the gear wheels, the latter rotating the paddles. By moving the handle back and forth through an arc comprising one-half of a circle a reciprocating motion is constantly Imparted to the paddles, this motion causing a greater agitation of the cream than would be caused if the paddles were given a continuous rotary motion.

butter churn.

AUSTRALIAN-MADE BUTTER CHURN

An all-metal butter churn made in Australia attracted much interest at a dairy factory exhibition on the Sydney Showground.

So if you're going to the Royal Easter Show this year

When: Daily, 10am - 5.30pm

Where: F20 - next to Farmyard Nursery and Woolworths Food Farm

How do milk, butter and cheese get from grassy paddock to breakfast table? Dairy Farmers Working Dairy takes you behind-the-barn-door to see the inside workings of a modern dairy. In this display of contemporary agricultural technology in action, you will see state-of-the-art machinery in operation, watch as cows are milked and learn how today’s dairy farmers monitor their herd for maximum performance.

Visit the Working Dairy and the nearby Dairy Farmers Milking Barn for a look at the incredible changes that present-day technology has brought to the business of agriculture.

Stay safe

When you come into contact with farm animals at the Sydney Royal Easter Show, just remember two simple rules: take care of the animals and take care of yourself. Download a copy of the

Stay Safe fact sheet.

The Royal Easter Show

LOCATION

1 Showground Rd

Sydney Olympic Park, NSW 2127

OPENING HOURS

Show opens at 9am

Pavilions open at 9.30am

Evening entertainment until 9pm

Showbag Pavilion til 9.30pm

Carnival until late

Also available