October 24 - 30, 2021: Issue 515

History Of The Modern Surfboat

Recognising The Surfboat Builders From 1950 To 2021

The first weekend of racing will begin with SLS SNB's Super Saturday, on the 13th of November! Round 1 of the Surf Boats Premiership will be held at Freshwater Beach. Round 2 will be held at Newport Beach on November 20th.

This document has been extensively researched to the point of reasonable accuracy with a lot of input from Surfboat people from each State and many hours spent on web and other searches. Apologies in advance to any boat builder missed, or for any detail not completely correct, as this paper is a best attempt to create a running history of surfboat evolution.

The motivation for creating this document was to give due recognition to each and every surfboat builder across many decades. Our sport has always been totally indebted to these builders for their knowledge, passion and craftmanship in the continuing evolution of the iconic Australian Surfboat. To each of the builders, we the rowers and sweeps, say thank you.

A Little On The First Surfboat Type

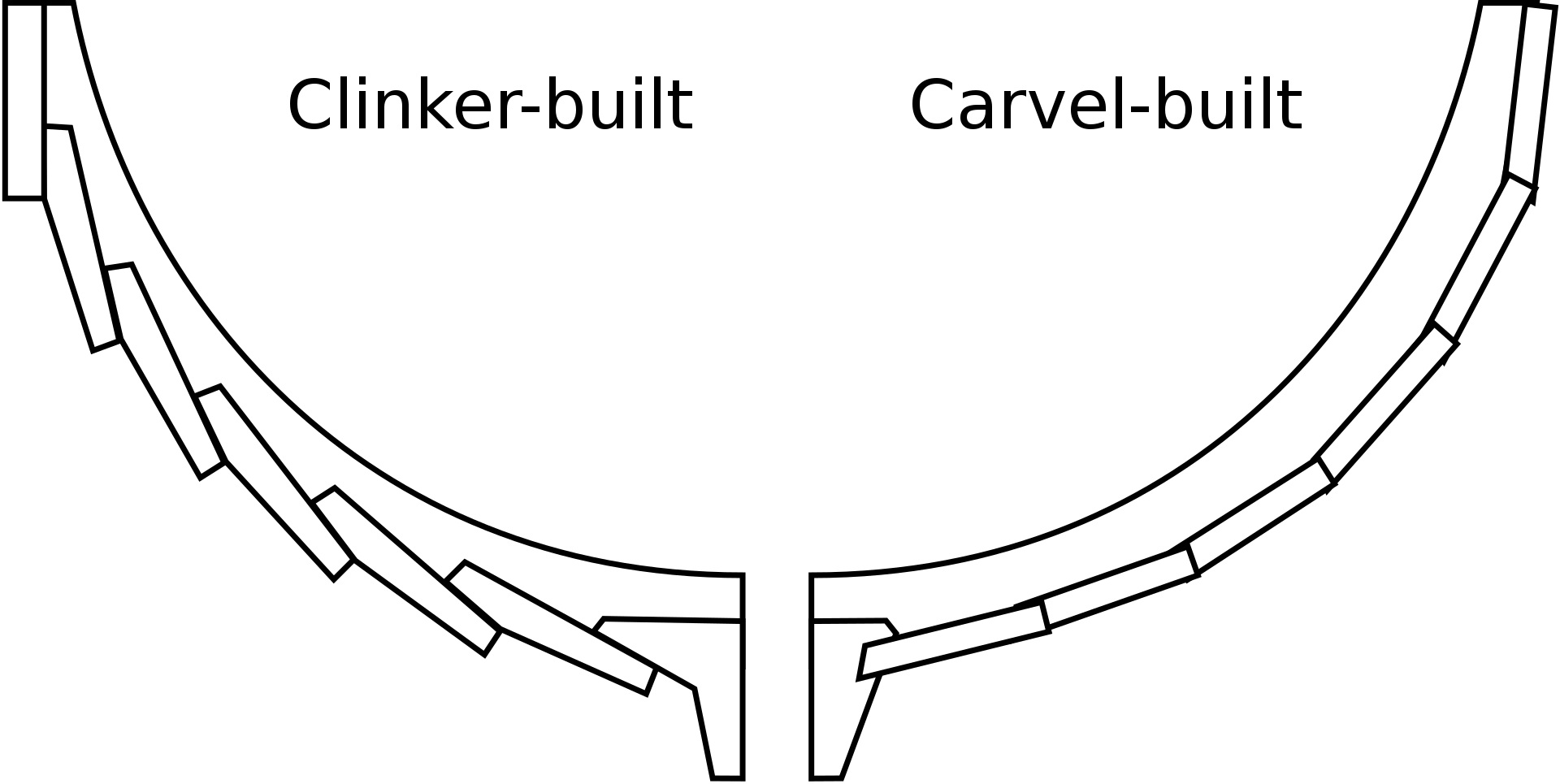

The earlier surfboats started out as a clinker and some builders also started to employ the Carvel build method (see diagram below). Both techniques had been around for centuries, but the clinker seemed to be the preferred method for the early surfboats, which were really the old Whaler style fishing boat. The early builders started playing with design during the 30s and that saw the start of a shorter boat with a lot of rocker or banana built into the keel. The clinker relied on a good tight lap joint to keep the water out, whereas the carvel design originally used a chalking method between the planks as in the old sailing ships. By the time this reached surfboats, the builders were using glues to seal the plank edges. The carvel plank needed to be thicker than the clicker plank and required more internal support, so were in fact a heavier option.

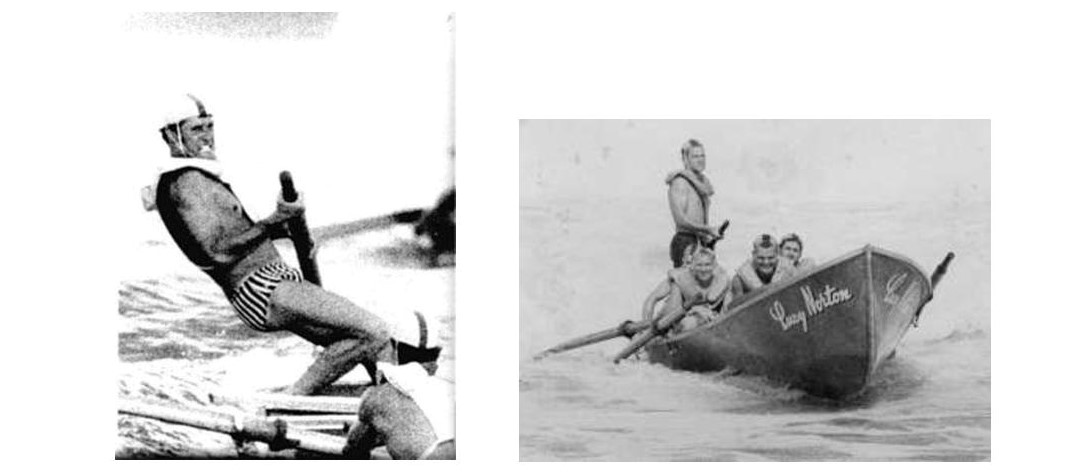

Photo below of surfboat crew training on Sydney Harbour in a pretty early Clinker with a rudder instead of the later sweep oar. A good example of the early crews not sliding but employing a very long lay-back to finish to the stroke.

The New Generation Of Boat Built From The Mid 50’S

The real starting timeframe for this article is after the introduction of the “Cold Mould” strip Veneer built boats from the 1950’s, which became the precursor of today’s modern Glass boat. Some of today’s boats are still the same old timber hull design copied across into new moulds.

The Yacht industry not unsurprisingly had a huge influence on shifting the surfboat construction methods from clinker to veneer, as many of the early builders were already master yacht class boat builders and sailors. The yacht builders had started to shift to ply construction during the 40s, in part taking their lead from what was happening in the aircraft industry from manufacturers like De Havilland. Around the time of WW2, a lot of research went into utilizing light weight timber veneer with different glues for aircraft building and this of course could easily be transferred into boat building. This included an early version of heated vacuum gluing of the veneer.

The first shift from the old double ended whaler style came in 1946, when Tom Humphries of Swansea designed and built the first Tuck stern surfboat in Newcastle, but this was still a Clinker/Carvel hull craft. The clinker & carvel construction had served our lifesavers well from the early 1900s, as they were a primary method of rescue, but they were extremely heavy and, in most cases only able to be transported to carnivals on the back of trucks.

Another common method was for the crews to row and or tow behind trawlers with the boat fully loaded with crew between different beaches. In fact, a few crews actually combined rowing/towing from Sydney to Newcastle for competition. It was common to virtually see the whole club being needed on the beach to assist in pulling the Clinker from the shed to the water and back again on rollers.

Through a desire for lighter boats using less timber, the obvious place to start was a complete overhaul of boat design. So, during the 50s, a major transition took place when the old timber Clinker and Carvel planked “Whaler Style Double Ender” boat was replaced with a lighter “Cold Mould Strip veneer” tuck stern style surfboat.

The new 50s Veneer boats had internal ribs and stringers like the original clinker, over which at least three thin layers of cedar veneer strips were glued and pinned at 90 deg to the first strip, making for a relatively light but immensely strong hull. The new cross-ply construction method saw a very ridged hull which allowed much of the original internal timber ribs and stringers to be removed. This made for a new boat that could be built to around the 210-220kg weight range. Overnight surfboats had changed for ever.

During the 50s this new Cold Form surfboat saw the start of a new more mobile era and with that the number of surf clubs involved in surfboat events grew swiftly. A number of shipwrights became involved in the new design concept around the country and clubs had a wide range of choice.

The boat shape from each builder was pretty stable in design and didn’t change a lot, but each builder had their own distinctive recognisable shape and each boat their own different characteristics. To say the hull didn’t change, I am referring specifically to the external specified dimensions. These ply boats were being built over a skeleton style Jig and the longitudinal strip supports of the mould were not always fixed to the mould, so could have wedges inserted to push or pull the finished hull shape.

Matt Clymer who took over the Clymer boat business from his father Bill informs that in the early years of the timber Jig the centre beam could be lifted of flattened thus providing a banana shaped keel for a big sea boat or a straight keel for a flat sea boat. Once built of course that was it - put a boat with a straight keel into a big sea and you have a submarine.

It’s important here to understand the few basic principles that dictate how the surfboat responds in different conditions to understand what the boat builders, and in turn sweeps, were trying to achieve.

❖ The more Rocker or Banana along the keel line the more lift the hull will have but it also makes for a slower running boat.

❖ Generally, the broader the tuck the less lift but faster downwind unless you make other changes to the hull to facilitate lift. See later discussion on the Slipstream design.

❖ A smaller tuck if combined with a bigger bow allows more lift.

❖ The longer waterline generally means a faster boat but also wetter, so conversely the short hull length the better the lift.

❖ The flatter the keel line the faster the boat, but that comes at the expense of lift.

❖ The positioning of foot stretchers to push the crew weight aft will allow more lift, but slow the run on the boat.

❖ To position the crew weight forward will encourage run at the expense of lift, but also if the weight is too far forward it causes the boat to dig in, thus pushing water which makes a slower boat.

❖ The width of the beam (hull width) also effects the hull displacement, which has influence on speed.

❖ The perfect all-round surfboat lives inside a combination of all the above, but what is that magical combination is the question.

So, when you look at the different builder’s shapes in the photos you can understand the evolution of the modern surf boat. Some boats display quite long bow decks, indicating a boat with the crew weight aft. Some very straight keel designs indicate a boat designed for flat conditions, while others had a lot of banana which made for great surf ability. It has remained a changing canvas of design from the 50s up until today, as boat builders strive to improve on design. However the current Glass boats are far less able to make radical shape changes due to the fixed nature of the moulds they come out of.

It can also be generally agreed that many timber boats were a one-off original, simply because of the ability for the builder to push and pull the hull. Today’s builders tend to have settled on their best hull shape and any changes are more tinkering at the edges.

As we know surf boat sweeps are all also self-endorsed Marine Architects and believe they know much more about design than the boat builder - at least in their own mind. So, understanding the different influence on performance of hull shape, and because the timber jig was somewhat adjustable, we saw many examples of a boat sweep twisting a builder’s arm - wanting to pull a little here and push a little there, looking for that extra yard of pace.

Every once in a while, one of these experiments actually worked, and along with the crew you would see a boat that seemed to be going pretty fast. Unfortunately, by the time the next club decided that they wanted to purchase exactly the same boat from Builder X, he had had another couple of boats on the mould and another couple of experts making changes, so no two boats were ever exactly the same, at least in most of the sheds.

The early timber boats had no internal tanks, so no floatation. If a crew took on water their only way to empty the boat was for one of the crew to down their oar and start bailing with a bucket, the very important piece of equipment always attached to the quarter bar. Some of the builders then started boxing in slabs of Polystyrene under the bow and rear deck, which offered some floatation, but at best kept the gunwales at water level.

Surfboats from the 50s into the 70s had to have fitted a bow line with 50M of line attached to a rescue belt, plus a knife. These were considered critical pieces of rescue equipment and in fact were often used for difficult rescues off headlands or from the back of the break, remembering the IRB wasn’t thought of until the 70’s. The Box Line was later replaced by a Rescue Tube, then the knife disappeared and today not even the Rescue Tube remains.

It wasn’t until the mid-70s that we started to see a small changing of the guard of the boat builders. Some like Barnett, Bailey, Beashel, and Phillips started retiring and one of the new kids on the block was ex Olympian and Champion Queenscliff rower, Roger Ninham among others.

Another feature of the 50’s and 60’s was the mode of transport to carnivals for the crews. The photos above are of crews being towed across Port Phillip from Point Lonsdale to a carnival across at Portsea. As can be seen several boats in the tow line with crews stationed in each boat. This was a very common occurrence back in the clinker boat era in Sydney.

Imagine obtaining insurance clearance for this in the 2000s.

Let’s Meet Our Builders

The listing of builders is not in any date order as that information isn’t available. Instead, I have tried to stick roughly to decades or eras.

Humphries Boats NSW:

Originally built under the business name T Humphries & Sons Newcastle, it was father and founder Tom Humphries that made the first Tuck stern surfboat in 1946. There were two Humphries brothers, Colin and Boyd, involved during the 50s to 80s, with Colin’s son Robert being sought out to build one further boat to keep the family boat building alive, after he retired his job as a Postie. The best example of who used the Humphries’ Boat was the great Swansea Caves crew swept by Ken Murray, but many clubs were Humphries fans.

Ken Murray at work in the back of a Humphries boat & Bulli Crew 1959-60

Humphries Boat built by Colin Humphries 1974

Bill Barnett NSW:

He had his shed right on the water at McMahons Point in Sydney and to collect a new boat it had to be rowed or towed away. Bill suffered a major shed fire in the early 70s and lost all his patterns and jigs, which resulted in him starting again with a completely new hull shape. Bill built his first veneer surfboat for the legendary Sweep Keith (Spaz) Hurst in 1956 and he went on to win the Australian Open Championship that year.

Bill Barnett was a master craftsman and in some ways was the benchmark for boat design and build. His early boats were about 23 feet long in the old scale with good banana in the keel and a nice flared bow. His later boats had grown in length to just over the 25-foot mark and like all others, had straightened out the keel to provide more straight-line speed.

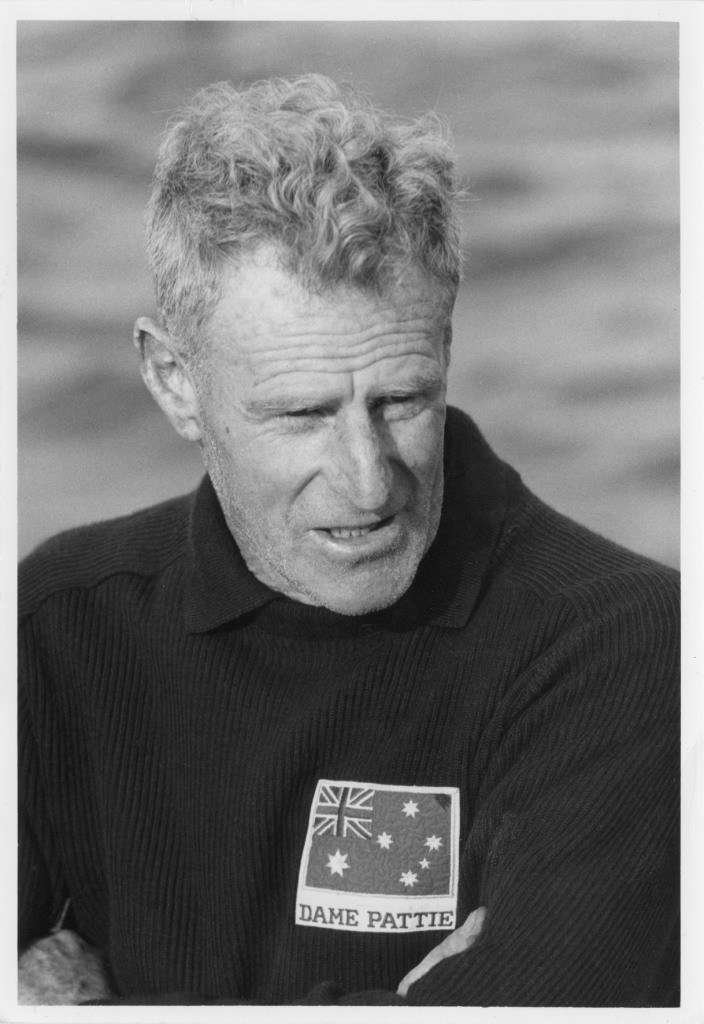

Bill Barnett was a champion 18 footer builder and sailor, a skill he easily transferred into his design and build of the modern surfboat. Bill was part of the design team that built and crewed the 1967 America Cup challenger “Dame Pattie”. He followed that up by building the 1970 America Cup challenger Gretel 11 for Sir Frank Packer. Bill Barnett died in 2018 aged 102.

Master boat builder Bill Barnett, crew member of the 1967 America’s Cup challenger DAME PATTIE, c 1967. Copyright. ANMM Collection Gift from Graeme Andrews

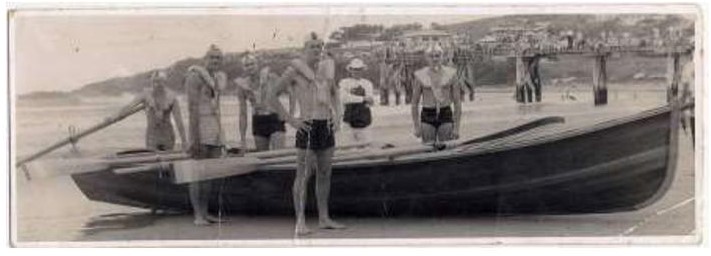

Barnett boat Port Macquarie crew 1961. Two ASRL Hall of Famers: Don McManus far right and Warren Malloy 3rd from left

Bailey Bros NSW:

Bailey Bros were oar and skiff builders who also built a few surfboats. We know that Nth Cronulla had a boat built in 1954 as did many other clubs. The following extract is taken from the minutes of the Coffs Harbor Surf Club in 1954:

“that boat builders Bailey Bros. be asked to supply one cedar tuck stern surf boat with spruce oars and an Oregon sweep oar at a cost of four hundred and sixty pounds; delivery by January 5, 1956.”

This is that first Bailey Bros tuck stern surfboat. Left to Right: Bill Pearce, Boyce Seccombe, Bill Palmer, Rear Alister Watt.

And again, the Bailey Boat in competition: Left to Right: J Fuller, A Watt, R Turner, B Seccombe, G Voigt Examiner & B Palmer.

Roy Phillips NSW:

He also built a lot of surfboats in Drummoyne during the 50s to 70s and his boats were considered fast, with one of the straighter keel lines. They included a flatter bottom and rounded hull that required good oarsmanship to set the boat up. Clubs like Sth Curl Curl, Freshwater and Merewether were known to row Phillips, and Spaz Hurst won an Australian Open Boat Championship with a very good Mollymook crew in a Phillip’s.

.jpg?timestamp=1634867564417)

Phillips 1952 Carvel Plank

Bill Clymer NSW:

A well-known Sydney boat builder whose boats are still available today, but now under new ownership. Bill built his first surf boat in 1963 for boat sweep John Winshuttle, who was with Palm Beach Surf Club Sydney. This boat had a drop-down keel which was engaged by the sweep pulling a lever to drop the keel down into the water. The big issue with this feature was that sweeps forgot to pull the keel back into the boat and kept ripping them off on the sand. The original Clymer boats featured a big tuck and a lot of banana in the keel line.

The first of the Clymer boats were much shorter that today’s craft. This allowed for good lift and manoeuvrability. As the crews started searching for more speed, the keel straightened and lengthened.

Clymer built his first Glass sandwich boat in 1978. Bill died in 2004, but had continued to work on the boats in the business (subsequently owned and operated by son Matt) until 2002.

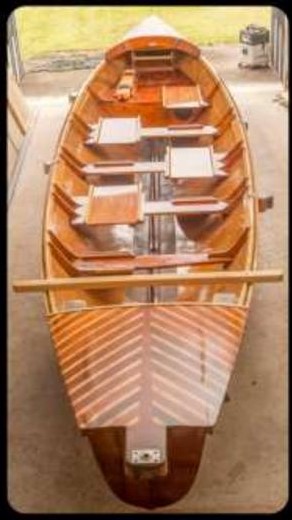

Restored 1971 Clymer surfboat

Restored 1971 Clymer boat in action with Freshwater old boys Crew

Ken Beashel NSW:

Ken was another Sydney yacht builder and sailor who expanded his business to include surfboats as part of his fleet.

The following is an extract contributed by Gary (Herb) Staples of the Port Kembla Surf Club on his club’s involvement with the Ken Beashal surfboat:

Port Kembla had three boats built by Ken Beashal between 1965 & 1971, each boat was completely different. They were all well-built but designed for different surf conditions.

The first one the H A Fleming was built from teak and was very light. Our open crew won the state in this boat ending Caves Beach’s four-year winning run.

The second boat built, the John ‘Scarlett’ O’Hara, named after a club member who was killed in Vietnam. Our open crew got fourth in the state in 1971 in this boat.

The last one was the Horrie Fleming. Was built for flat conditions, and had a bow shaped like a wedge, a straight keel with a small tuck about 350mm wide & 450mm high, and a very fast boat in flat conditions. In a surf it was like a submarine as it tended to want to go through a wave not lift over it, no pumps in those days. In a flat surf at the Australian in Burleigh Heads in 1973, our open crew finished fourth in this boat.

This is the very typical experience of many surf clubs where they worked directly with the boat builder looking for a boat that both suited the crew and usually the expected conditions at the next Australian Championship location.

Two of the Port Kembla Beashel Surfboats from 1965 & 1971

Ken Beashel in 2014

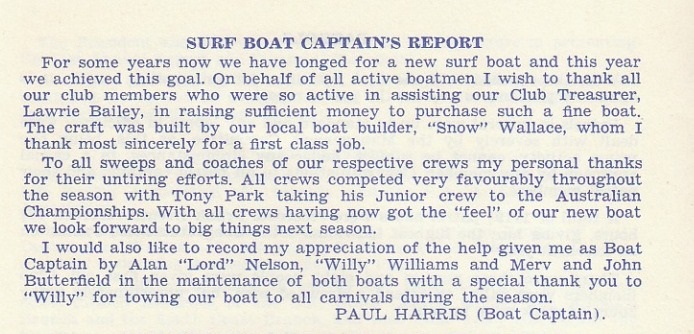

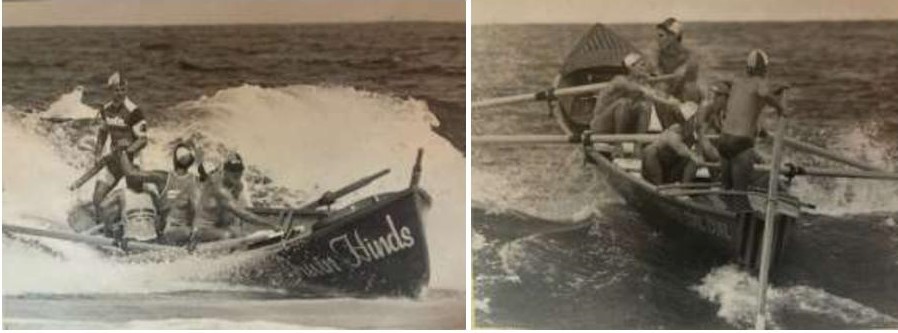

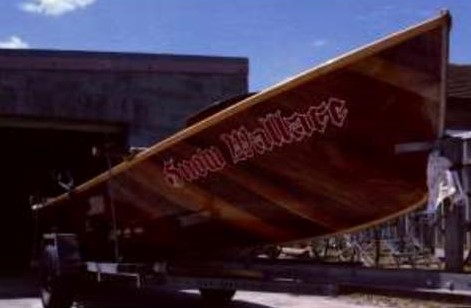

Arthur (Snow) Wallace SA:

Snow built boats in South Australia during the 50s to 70s, mainly for SA and South Africa, with we believe some ending up in the UK. Snow Wallace was contracted to build 6 of the BP boats for SA between 1960 & 66. The SA crews loved their Wallace boats that were very comfortable and capable surfboats.

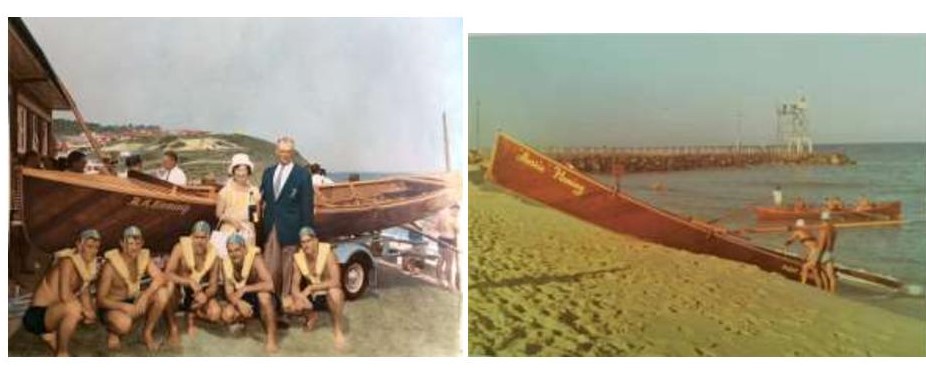

from - Henley SLSC, 1965 annual report

Like all the timber builders a major part of their work was repairing boats and oars after a weekend’s carnage. Locals well remember the outside of the Wallace shed being cluttered most Monday mornings after the weekend’s misadventures.

A look at the finish in the photo below clearly indicates the quality and love that went into each surfboat.

Snow Wallace boat built for Brighton. Crew Left to Right: Barry Hancock, Graham Reid & Warwick Archer.

Wallace on the water

Bill Ninham WA:

Bill (Rodger’s father) built surfboats in Western Australia and was well known for his fine craftmanship. One of his last boats was built for the famous 1977 Aussies at Bancoora, coming away with a medal. By 1979 Bill had retired, but was encouraged to design and oversee yet another boat for Swanbourne Nedlands SLSC, that was built by Bill’s son-in-law Chris Lewkowski. This boat won the 1979 Reserve Boat final at Trigg Island Aussies that year.

.jpg?timestamp=1634870255811)

Beautiful Ninham boat. 2nd photo with 1979 Australian Reserve Grade Surf Boat Champions. P. Wales, R. Bosworth, K. Jolly, I. Hodgkinson, G. Olsen.

John Stringfellow was Club President in 1991 and prior to this was Surf Boat Captain for 14 seasons. John recalled the following:

“We donated Cygnet V to the Fremantle Boat Museum when we ran out of room in the boatshed for the Norm Rees II surfboat that was purchased from North Cronulla. Tuppy Lahiff (a great surf competitor helped restore boats at the museum) and as such I considered it would get well looked after. Cygnet V had virtually not been used from 1979 until it was donated to the Museum and as such it was still in good condition. It was one of the last, if not the last, boats built by Bill Ninham who also built the Cygnets II, II and IV. I admired Bill greatly as he was a mentor to me from when I was in my first year of sweeping. I felt donating the boat to the Museum would be a tribute to both Bill and to the 1979 crew plus a few kudos to the Club. The boat was too good, in my opinion, to be thrown out and as the style was a bit unorthodox and old fashioned it would not have been wanted by any other club which would treat it in the manner that reflected it’s history.”

“Sundry equipment – Colour: From 1964/5 Swanbourne boaties wore Footscray football jumpers as their club identity (and to keep warm) and painted their oars with red, white and royal blue stripes.”

Cygnet V surf boat on display at the new WA Museum

“Cygnet V was built by Bill Ninham in his backyard workshop in Howick Street, East Victoria Park (Lathlain) and launched in late 1978. Bill was then a pensioner and the boat was nominally built by his son in law Chris Lewkowski whose boat builder’s registration should be seen etched into the boat’s inboard keel. Bill provided the design and the labour.

The Club ordered a new boat from Bill as a replacement racing boat for the Cygnet IV which was then 5 years’ old and was showing its age. Cygnet IV was arguably the Club’s most successful boat having been jointly designed by the legendary Cottesloe SLSC sweep Arthur “Danny” Kay and Bill and was the second of its type off the mould. It had a V shaped hull to enhance its speed but which was considered to slow the buoy turns. Bill was asked to design a boat with a more rounded bottom hull. When Cygnet V first came off its mould its higher bow made it looked more like a Viking longboat then a traditional surf boat and this may have influenced the A crew’s opinion of its racing ability.

The Club’s logo on the bow was in the spirit of the 1979 150th Anniversary commemoration of the European settlement of Western Australia when the State government had a similar logo of a rampant swan with a golden sun behind it. Our logo had a rampant swan rising from a blue ocean against a crashing white wave and a setting red sun.

The oars and sweep were just plain varnished. As I recall these were the new oars supplied with the boat. I think the club had only one good set of oars painted in the blue blade with red and white bands, and they were used by the A crew.'' -

Boyd Boats QLD:

These were designed and built by Claude Boyd at Landsborough Qld. The early examples we found were from around the 1964 season and Claude retired from boat building in 1985. Many clubs on the east coast rowed the Boyd with good success.

Claude was an old NSW Swansea man and cousin to the Humphries brothers, so boat building was very much a family thing to do. Claude Boyd died in Qld in 2011 aged 95.

1968 Boyd Boat

More examples of the Boyd surfboat - 1980 Boyd at Merewether

1981 Boat; The Boyd boat had good surf credentials and a popular choice especially in Qld.

Geraldton Building Company WA: Only built one surfboat in WA during the 60s, but no other information is available.

Laurie Chivas WA: Chivas Marine won the contract to build 6 surfboats for British Petroleum (BP) during the 60s in WA. BP sponsored about 6 surfboats in each State at this time. They were balloted in some way to different surf clubs.

Les Rimmer WA:

Les was another of the Western Australian boat builders. We found one image of a Rimmer boat hanging in the Maritime Museum Cornwell UK. This boat was built for the Floreat Surf Club in WA in 1963. It is believed to be the only surfboat Les Rimmer ever built and yet it ended up on the other side of the world in Cornwell.

Mouldcraft VIC:

This company was a Yacht and Skiff builder, but also built veneer surfboats in Vic during this era. This was a very interesting design, having a very wide tuck and an extremely long raking bow. If we look at the much later Slipstream surfboat it is interesting how close the 60’s Mouldcraft and much later 2000’s Slipstream were in design concept. Absolutely no suggestion is made that one copied the other - more that they were both built along the wide aft sailing style with a very different approach at the bow end.

Anglesea crew during the 66-67 season in the Mouldcraft Surfboat

.jpg?timestamp=1634871386488)

Internal of Mouldcraft noting reverse Rig, Jackets & Helmets plus the heavily raked bow

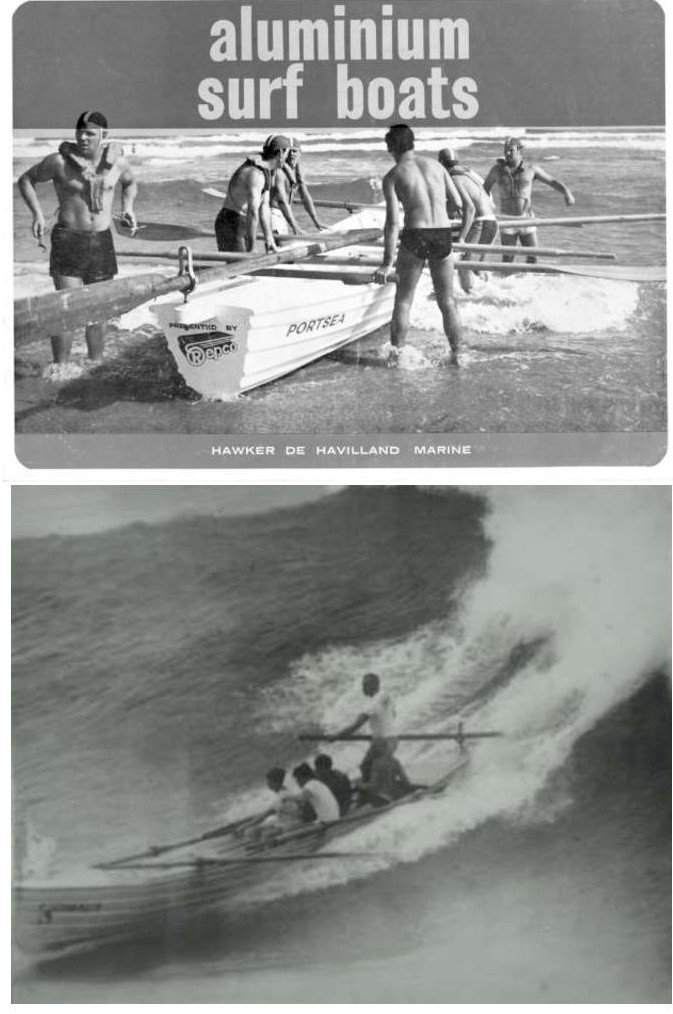

Hawker De Havilland Marine:

This company also decided to enter the market with a full aluminium boat during the mid-60s. We know that Cronulla, Nth. Narrabeen and Portsea each had an aluminium surfboat and a photo exists of another at Swanbourne Nedlands WA. We understand that one also went to a Gold Coast club. Rowers who had the rowing experience told of a very different sound coming from the hull and a pretty hard landing if being tossed about. The idea was to make an indestructible surfboat, but it was soon found the metal was no match for timber in the handling and speed stakes.

Nick Dixon on Sweep, Cronulla crew, Aluminium boat, wave off Cronulla

Ninham Boats NSW:

Rodger was revolutionary in that he came with a good Stillwater boat rowing and building knowledge and started to really play with hull shape and weight distribution.

Rodger did his apprenticeship in his father’s (Bill Ninham) WA sheds before moving to Sydney as a river boat rower and builder. He went on to work for some time with Bill Clymer, honing his skill and knowledge in surfboats.

Rodger was also a leader in refining the rowing stroke in the surfboat world, having represented Australia in the Eights at the Rome Olympics in 1960 and then switched to a Pair where he rowed in the Perth Comm games in 1962 and the 1964 Tokyo Olympics. Remarkably Roger was rowing heavyweight at 6 foot and 77 Kg so pulling way above his weight.

He manufactured his first Surfboat in about 1970 and his second was ordered by Warren Malloy of the Queenscliff Surf Club in 1971. Warren ordered the Ninham boat on the condition that Rodger joined the crew which he did and along with John Pool, Dave Baldwin and Rob Burgess they rowed in 24 events during the season, winning 20, which included winning the Australian Open Boat Championship. This 1971 boat was the first to include a double quarter bar. After that 1971 success, the Ninham Surfboat became extremely popular and the business took off. Rodger was extremely giving of his time and experience and many surf club crews from city to country tapped into this knowledge.

During the second half of the 70’s he started adding a layer of glass sheet over the ply hull to give it more rigidity. He also started working closely with some sweeps to trial very different hull shapes. One that sticks out was a boat he built for Peter (Grub) Grant and the Torquay club and possibly a second for Nth Bondi. It had the tallest bow Stem, possible sitting 1500mm high on the sand and the smallest tuck maybe only 250mm deep. It looked like a bomb and it performed like a bomb, but at least they tried.

Rodger manufactured his first Foam Sandwich boat in about 1980 but he continued to also build in timber as some crews still preferred the timber craft.

Sadly, Rodger died way too young in May 1985.

Rodger Ninham the Australian Sculler & his 1983 Surfboat. Note the short Bow

First of the Ninham Glass boats 1980. Photo of Moruya Crew.

Other builders starting operations in the 70s to 80s and these included:

Ron Corby NSW: Ron started building a few timber boats in Kiama and then shifted his shed to Braidwood. Ron was another who manufactured timber rowing and sweep oars and built his first boat for his Kiama crew in the second half of the 70s.

DeJong Boats QLD: Nick DeJong started building surfboats in Qld in the early 1960s. It’s not known how many DeJong boats were built, but it was several.

This in the DeJong in action.

Miles Boats NSW: (Contribution by Nathan Perry)

Bob Miles became a very successful Sydney boat builder, also utilising the ply wrapped in glass method from the very early 80s into the early 90s. Bob was a shipwright in the naval shipyard and luckily for the sport he retired to build surfboats.

Bob Miles progressed from an all-cedar hull of 3 skins, diagonal, vertical, and finishing with a diagonal 90degrees to the first skin, much the same as all the other traditional builders at the time. Also, spruce stringers and silver ash laminated timbers or ribs were still used. This was varnished with no sheathing of any kind, just a ton of varnish.

In the 87-88 season he changed production to 2 skins of Gaboon ply. Again this was built over a male mould (see photo below), the same as the cedar boats. This was then sheathed with an epoxy resin and 10oz or 300gm cloth. The outside was varnished or sometimes painted. The inside was also sheathed and always painted.

The boat was fitted out the same way as the traditional boats with thwarts and knees, but the sheathing saw Miles do away with the stringers and ribs. It was at this time we saw both Clymer and Miles start to build air tight buoyancy tanks at either end, incorporating the bow, including under the bow seat and the aft in the sweep’s area. Initially, Bob was making these buoyancy tanks out of ply.

In my time at Miles', we built 3 one off foam hulls the same way we built the timber boats over the male mould. One for Grub Grant at Lorne, one for Michael Brown at Kurrawa and a marathon boat we built for Queenscliff. This boat for Queenscliff would have to be one of the most interesting boats of our time and it's lost. It was the same as all boats forward, probably a bit bigger volume than the ply boats, then from about mid way changed and developed a chine that grew more obvious to the tuck ala the Phillips boats they would have been introduced around the same time.

The Miles boats also ventured into the foam sandwich era, Bob Miles was one of the most successful builders of his time.

Bob died in 2001 of asbestosis contracted its thought from the earlier shipyard work environment.

Bob Miles Jig – still available today if anyone wants a timber boat at Mike Taylors Qld shed

More examples of the Miles Boats in action - 1992 Miles Boat with Sth. Curl Curl on board.

Skilful Boat Builders

By way of understanding the skill of our boat builders this boat that was smashed at the NSW State Titles in Thirroul in 1992 and ended up in three large and several small pieces went back to the factory for repair. Three weeks later it had been spliced back together and won a medal at the Australian Championship.

This section was re-joined to a large stern and another sizable side panel.

Taylor Boats Illawarra NSW:

Father & son Max & Peter Taylor from Woonona in the Illawarra had a successful business right through the 70s & 80s, firstly with timber boats for a number of years and then they moved into the glass revolution completing several glass boats.

Max & Peter Taylor boat being Launched at Towradgi & Bulli 1974-75

Graeme King SA:

A stillwater boat builder from South Australia, Graeme was coerced to build several surfboats. He took on the Snow Wallace mould, made some modifications and build a number of very nice-looking surfboats. Graeme moved his small skiff boat business to America in the 80s and was lost to SA surf clubs. Graeme has recently returned from America to retire to Port Pirie SA.

.jpg?timestamp=1634872888419)

King Surfboat with Christies' Crew on board.

Bruce Keir VIC:

A Victorian boat builder who was also active around this time. We do know that one of the boats he built was for Brighton SA and named in honour of the very popular SA surfboat builder Arthur (Snow) Wallace.

A wonderful example of the skill of the boat builders. Bruce Keir built.

Bob McClelland Boats NSW:

Bob was the first to build a glass sandwich boat in 1977. Bob then decided after creating his mould to build the first unsinkable surfboat.

Bob was an innovator and decided (before pumps) that an empty boat would be a winning boat. He raised the floor up to seat level and created indented self-draining foot wells. Right along the side, just above the floor deck, he installed self-draining scuppers that with the internal buoyancy created by the raised floor, simply allowed any water to wash straight out of the boat. The first unsinkable boat built was for his Burning Palms club and it quickly won the name of “Yellow Submarine”. Finished in bright yellow, it could be seen being buried and rolled under surf and immediately self-righting and draining. It was a good boat, but pretty scary for the crew when coming aft on a big wave with such a high centre of gravity.

Taylor Boats QLD:

Father and son, Ron and Mike Taylor (no relation to the other Taylor), built Veneer constructed boats at Slacks Creek QLD during the 70s to 90s. Mike is still manufacturing Timber Sweep oars at his QLD factory. Mike Taylor still has the old Bob Miles mould in his shed just waiting for a surf club somewhere to ask him to build one more timber surfboat.

Beautifully restored Mike Taylor Surfboat.

Mackay Boats NZ:

A few New Zealand made boats built by Jim Mackay also found their way to Australia. One of the NZ crews shipped a MacKay boat to Australia for the 1988 George Bass Marathon and left it in Australia at the end of the event. The big difference, (beside the very straight keel) to the boats being built in Australia was that this boat was manufactured using a single skin fibreglass method, no foam composite and the internals and gunwales were all timber.

It was a very straight waterline boat and at one stage Croker Oars actually manufactured a couple of these boats at Taree, as did Gus McDonald of South Coast Surfboats who had taken a “flop” off an imported MacKay, but only made one boat.

Early example of the NZ MacKay boat in timber.

Period Of Change

The period between the 80s and 2000s saw a lot of development from all the boat builders and saw the explosion of composite sandwich construction in glass boat building. This was the era where both inner and outer construction started as Foam Sandwich glass coated and then in some cases the internal sandwich was replaced with an internal fixed one-piece tank. Internal buoyancy was maximised, two electric pumps fitted and the next generation of surfboat was born.

New builders to emerge during this period were:

Angus Humphries NSW:

After the retirement of the Humphries family, Graham Angus was given permission to take what’s called a “Flop” off the Humphrey timber hull and convert that into a mould. Graham proceeded to manufacture a Foam sandwich boat, which he called the Angus Humphries, in QLD for several years starting in the early 1980’s. It’s unclear just how many of these boats were made, but it was several.

Angus Humphries boat circa early 80’s – fitout & finished.

South Coast Surfboat NSW:

Graham (Gus) McDonald introduced the South Coast Surfboat in 1985/86. After the sad passing of Roger Ninham in 1985, the family permitted one of his last timber hull boats to be “flopped” and transferred into a new fibreglass mould and the South Coast Surfboat was born.

The first of the South Coast boats was built by Moruya Dentist Graham (Gus) McDonald around 1986. The first couple of South Coast boats were built under the SLSA Experimental tag, which allowed innovation in design, but the boat could still be used in competition while agreement was reached on specification change. The first boat featured no keel, which was now possible in Glass where the timber hulls had a full-length solid timber external keel. The second boat added a very small half-moon shaped keel under the Stroke feet which proved to be a very good design for manoeuvrability. This keel change started a debate by SLSA and finally a specified keel size was written into the specifications some years later. Gus also introduced the internal buoyancy boxing under his boat seats along with a centre channel designed to funnel the water straight to the pumps, giving the boat more buoyancy and a higher centre of gravity. Before Gus made this change, boats had an open internal design which allowed water to flow freely around the hull not always to the pump (singular at that time).

Like Rodger Ninham, Gus was into innovation and he was determined to change the internal fit out of the surfboat away from timber struts and knees to a clean all sandwich composite finish, initially because Gus argued it would make a safer boat with no internal hard edges for the rowers to dodge. That required SLSA to agree to his changes which finally saw thickened sidewalls around seats and thwarts and a pretty major rewrite of the build specification. After seeing a NZ built MacKay surfboat in 1988 Gus was convinced that single skin construction was the way to go. He didn’t manage to convert his building method away from composite to Single Skin for the Hull but was a big pusher with the next business owner for the single skin. Composite hull at that time could have issues with taking on water and thus weight so Gus saw the single skin was a next logical development step before “Infusion” construction methods used by later boat builders.

Gus sold the business in 1991.

South Coast Surfboat built by Gus McDonald.

The Boyd Richardson QLD:

This boat was brought back to life in 1986 by Qld Boat Sweep Lofty Richardson who had been a long-time user and advisor to Claude on hull design. Lofty, with the support of Claude, took over manufacturing the Boyd boat, but this time in foam sandwich. Lofty changed his construction method in the mid 90s to join South Coast Surfboats as a single skin style boat. Over his time Lofty built about 70 surfboats until he also retired from boatbuilding in 2006.

Boyd Richardson on the water.

Boat Beavers WA:

A couple of clubbies from City of Perth, calling themselves Boat Beavers, built one boat for City in the late 80s, but that was a one-off effort.

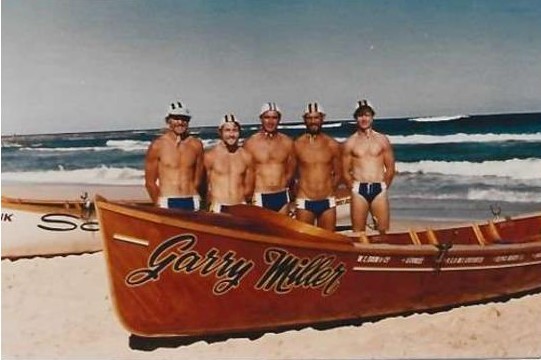

Clymer Boats NSW:

In 1988 Matt Clymer, a very successful boat sweep with the Manly club, took over the building of these boats on the retirement of father Bill. Matt continued to build the very popular Clymer boat by now fully utilizing the foam composite construction method. Many crews will argue that the Clymer boat is their preferred surf boat for surf conditions.

Over the next decade Matt shifted focus from the built in internal composite foam fit out as had been the norm for all craft during the 80s through the 90s, into the development of a complete internal mould. Like any major new change, especially in a craft that was subject to the extreme external pressures of a surfboat, the new one-piece internal section took time, but the end result was well worth the wait.

Rick Millar and Avalon Beach.

Peter Spence and Palm Beach.

Burton Boats NSW:

Ray Burton was the Burton of the Sargent and Burton famed stillwater boats and oar business. During the 80s Ray Burton branched out to design and build a revolutionary new glass surfboat. This boat was a very different hull shape, especially at the bow end and with a vee shaped tuck. It enjoyed good success, production started in the early 80s and ran into the early 90s. The production method was also different to all the other builders of the time. The Burton boat was built from the outside, meaning that the foam was laid over a mould and the glass and gel coat applied to the outside of the foam.

The hull was then lifted off the mould and the inside glass coats applied. Other builders were using the mould system where the first layer applied was the gel coat, then the glass matte, then the foam and finally the internal glass mesh. The finished hull was them floated out of the mould.

The early Burton had a very short 150mm deep keel centred in the length of the boat which allowed the boat to spin on sixpence. It was this variation of keel that finally saw another formalisation on the actual surface area of the keel which still exists today.

Ray Burton was the only builder to produce aluminium oars, it was an experiment that didn’t last.

First ever Burton timber surfboat.

First Glass Burton at start of the George Bass. Penguin men in the Burton Boat.

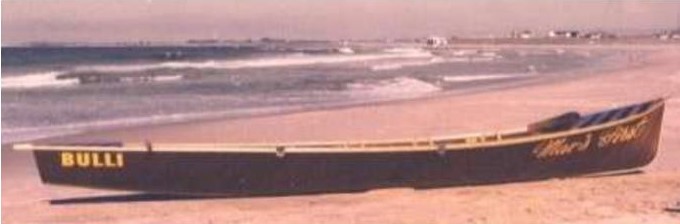

South Coast Surfboats NSW:

New owner Ron Kelly had purchased the SCS business in 1991 and shifted production from Malua Bay to Ulladulla. The boats continued to be built to the same specification but he did make the shift from composite to single skin in the early 90s. Ron made the next big change by removing the timber gunwales and replacing them with a new improved closed cell foam composite gunwale. There was a lot of apprehension from crews at the time as all builders started to convert to the foam gunwale for fear around strength and the ability to hold the rowlock housing securely. This apprehension soon gave way to acceptance when the new gunwales proved themselves to be well up to the task.

Ron Kelly sold the business in 2003.

.jpg?timestamp=1634876497868)

Examples of the boats produced by Ron Kelly. Bulli, Robbie Meijer on Sweep, Chris & Rod Mercer – International v NZ

Examples of the boats produced by Ron Kelly.

Dennis Phillips NSW:

Somewhere in the 90s, Dennis Phillips, son of Roy, who built in the 50s/60s, was sought out by Swansea Belmont Sweep Trevor Dyson (son in-law of the great Ken Murray) to build a one-off special boat. The base waterline was quite radical in that unlike all other boats it featured a flat almost planning bottom. It had some rocker on the keel but two distinctive flat sections either side of the keel. About 4 of these boats were made, 3 for Swansea and 1 for Maroubra. The photo below of the hanging boat will show the underside design. The photo of the boat and trailer clearly shows the side drain scuppers. This boat was the only other version of the self-draining hull with a very high deck first introduced by Bob McClelland in the 80’s. It straightened out the gunwales to make all rowlocks equal, but the biggest innovation was the introduction of distinct chine lines not before seen in modern surfboat construction. The finished look was square and chunky, but boy, the Swansea crew knew exactly how to row it and it was a flyer. This boat was never planned for mass production and was a good example of thinking outside the design box.

Dennis Phillips high deck & self-draining scuppers below flat bottom and chine line.

Perry Boats NSW:

Nathan (NR) Perry completed his apprenticeship with Bob Miles and commenced his own business as a 23/24-year-old in 1997 and continues today with his own design and built Perry brand. Nathan built his first competition boat for Sth. Curl Curl who in 1997 went on to win an Aussie Title in that boat. Like many builders NR was searching for his own distinctive style of boat and for the first few years tried to manufacture a series of “one off” design boats, each that little bit different. He quickly realised that wasn’t going to be his long-term approach and set about stabilising his design into an all-round boat that he could repeat with consistency. Over the business cycle Nathan has had only one major design change and is happy that his product provides a boat suited for all conditions.

As the only boatbuilder/shipwright currently building surfboats that started by developing their own original design concept from scratch, we will devote a little time into understanding the thought process of a boat designer. We can probably guess that the following process would have been exactly the same for each of the original builders in both timber and glass as they attempted to balance the various options for speed and lift into their own surfboats.

Nathan Perry watching the action - Bilgola SLSC Surf Boat Carnival 2016

The following is contributed by Nathan:

Phase one in all building projects is design. For Nathan it fell to his mother, Kristine Perry, to help him draw the line plan for the original 96 design and it took 4 days to complete the setout work and draw the plans. The first 3 boats were built as one-off foam boats all laid up over the male mould and there was staged progression from the first boat along the road to what was to become the final design.

Boat one was for South Curl Curl and was a one-off foam hull, timber decks and gunwales and a one-off foam interior.

It was in late 97, still looking to settle on the best design and after observing the radical Dennis Phillips boats and the pics of the “Flora Roberts”, a boat Roy Phillips built for SCC in the 1950s, that the concept to cut down on the unnecessary volume in the aft of the first boats was decided. The plan was a weight saving of mass and also to adjust the rigging. Up to this point the stroke seat was getting higher than the 3 seat from the water line, which didn’t seem right. Also, during this change the stem was cut down by 50mm to reduce the bowman’s height from the water. The changed design concept was for the boat to look straighter with less banana by design. The aim was also to have all rowers seated as close to the same distance from the water as possible. The changes to the mould also included some work to the actual hull shape. This entailed a flatter section to the rear underside. This boat was the first Perry boat built with foam gunwales, one-off foam interior and was the first boat with moulded decks.

At this point we were feeling comfortable with the design so a Flop (copy) was taken off the last boat and converted into a mould from which we started building future boats.

In 2017 Matt Clymer wanted to retire and sold the Clymer boat business to Nathan so today Nathan Perry is building both the Perry and Clymer surfboats in his Sydney factory.

Perry surfboat in the hands of Nathan and Manly LSC men

Nathan Perry with Manly LSC Boaties Division at Newport, 2017

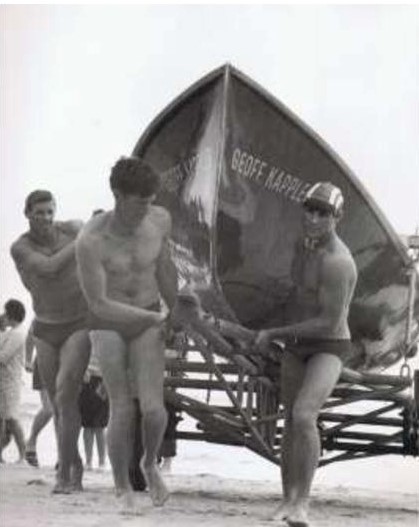

DKG Boats NSW:

Drew Griffith also completed his apprentice in the Bob Miles shed and in the years that followed built the first new DKG boat somewhere in the late 90s. Drew was a successful boat sweep, firstly with the Nth Narrabeen club and he came to building surfboats with both the knowledge of a boat builder but also of a boat sweep. DKG boats became very popular as clubs embraced the new designs and building methods. The DKG also embraced the one-piece internal fit out coupled with a composite foam sandwich hull.

At the start of the 2000s, with some retirements from the industry, the boat builders left standing were:

Clymer - was building a sandwich glass boat with a fitted internal tank.

South Coast Surfboats - building a single skin glass boat.

Boyd Richardson - building a single skin glass boat.

Perry Boats - using the sandwich construction method with an internal tank.

DKG - using a sandwich construction process and internal tank.

Slipstream - using a Sandwich construction process.

Major Changes

The big development for Perry, DKG and Slipstream at this time was in the construction method. All builders had been laying up the glass boats with different layers of stitched fabric or woven cloth and resin inside the mould. The one difficulty with this method of application in the composite construction was to achieve consistency with the amount of resin applied in equal proportions along the whole hull. It was possible, even with the best efforts, for boats to come out of the mould at different weights.

The game changer for the composite builders was the introduction of the “Infusion” method of applying the resin. The Infusion method basically is one very big plastic vacuum bag that is tapped around the outside of the hull mould and draped inside. A large vacuum pump type machine is then connected to an outlet suction hose and a second inlet hose to the resin. The resin is then basically sucked inside and through the foam and glass laminate under the plastic bag. Under immense pressure, the resin is forced or sucked right through the hull, filling every hole and crevice in the foam until it is drawn right up to the gunwale level. This is a very accurate method of applying the resin and can control the thickness of resin to extremely small margins, providing a boat of very consistent weight.

The Clymer boat at this same time was using a vacuum to form up their foam hulls in the female mould. They would gelcoat the mould, glass the outer skin, then just vacuum the hull foam down onto a very wet cloth or slurry. You didn't need a complete vacuum to achieve this, just a good amount of vacuum to press the foam into place while the ''glue'' went off. They would then pull off the bag, bog up all the gaps and holes and glass the inner skin.

The other manufacturing method is the “Single Skin” employed by South Coast Surfboats. This method has completely removed the foam from the hull, so the boat is laid up in layers of Glass Mat impregnated in Resin. It is the same base product as used in the Infusion method without the foam. The Single Skin method is also very accurate as all raw materials are weighed at the start and the builder knows exactly the weight of the finished boat from the quantity of materials used.

DKG Hull and Internal being Infused separately before being fitted together.

South Coast Surfboat being Laid up in the Single Skin method.

Slipstream NSW:

In the late 90s to first half of the 2000s, Gavin Clark decided to engage a Marine Architect to look at surfboat design and the result was the Slipstream surfboat. It was another big shift away from the conventional surfboat design with a very wide Yacht style Tuck. It featured a short stub nose that was up to 200mm wider than other boat designs at the splash rail.

Many of the experts decided before it even hit the water that it wouldn’t work. Well, it challenged the traditional convention on style and it did in fact work, being favoured for a number of years by many crews. The wide flat tuck provided a great platform for running conditions. The wider nose with its additional volume above the waterline up front provided the lift. Slipstream went straight to a composite foam sandwich construction, utilizing the vacuum “Infusion” method.

Slipstream in Action notice wide Tuck and width at Splash rail.

As of 2021, the following boat builders are still visibly active in the market selling into Australia and New Zealand:

Clymer Boats NSW: In 2017 Matt Clymer retired as a boat builder and sold his business to Nathan Perry. Nathan has continued to build both the Perry and Clymer surfboat in his Sydney factory.

Perry Boats NSW: Nathan Perry has developed his brand to be one of the very popular surfboats on the market. The Perry business can now offer the choice of either the Perry or Clymer surfboat. Both boats still hold onto their unique design performance features. Both boats are built using the exact same production method.

South Coast Surfboats NSW:

In 2003 the Bean family purchased the business and after remaining for some years building out of Ulladulla, they eventually shifted the factory to the Sunshine Coast. Jase Bean took over the actual building from his brother Wes when the factories changed location.

Jase & Wes started to play with the design firstly adding a lot wider front Gunwale to keep the boat drier. The next stage was a slight increase to the volume of the bow above the waterline that completed the concept for a drier boat, while not changing the waterline. The boat is now the only surfboat built using the single skin technique and built-in internal bulkheads. One feature of the single skin is it can’t take on weight over time.

The modern version of the South Coast Surfboat with Bulli on board

The South Coast Surfboat like the Clymer is a hull born from a 70’s timber boat and basically remains true to the original design. Changes have been made in the method of construction and the improved performance in surf, but both the South Coast and Clymer are testament to the longevity and skill of the original builder’s design.

DKG Surfboats NSW:

One of two boats built in Qld. In 2009 Drew Griffith sold the business to a new group including two Sweeps and a Photographer - Grant Wilkinson, Mark McDonald & Harvey Allison who have continued on building boats for clubs in all states. The DKG is a well-balanced surfboat that has enjoyed success in both flat and big surf conditions.

DKG Boat - Bondi in action

It is interesting and important to note that of the four remaining surfboat designs all have performed well in all surf conditions. It is also important to mention that each of the builders are also all very competent boat sweeps, so clubs can confidently know they are talking to a boat builder who really does know their business from all sides.

Summary

To conclude, across the last 7 decades crews have embraced all of these different surfboat manufacturers. Clubs at times shifted loyalties for reasons of perceived performance, availability and cost.

What hasn’t been mentioned is the quality of the craftmanship exhibited by the timber boat builders. The timber boat was partly taken for granted when we stood on the beach with a couple of hundred beautiful timber boats on display, but in reality, the build quality was more like what you would find in a fine timber furniture shop. These boats were built by quality timber craftsmen, beautifully finished in marine varnish.

What we have today is equally a quality product, but a very different product now built for lasting performance and endurance. The modern surfboat by comparison is possibly faster, certainly lighter and a more buoyant craft, perfectly suited to balance the requirement for speed and surfing ability. The modern surfboat is a credit to the builders who manufacture them, each with that same sense of love and pride as the early timber tradesman.

For those sweeps that have experienced steering boats manufactured from the early 60s to today, each change has been noticeable. The early timber boats were heavier, the 50’s and 60’s boats were highly manoeuvrable until keels started to lengthen in the quest for more speed. The timber boat tended to cut its way through the top of the wave whereas the lighter glass boat wants to go up and over. The modern-day sweep has to be a bit more aware because the lighter more buoyant surfboat will bounce, swing and roll a lot faster than the older timber surfboat, but both are equally wonderful craft.

In the era of the 50s to early 60s all these boats had much shorter timber seats. Crews were rowing a style with a lot less leg/bum slide and a big emphasis on upper body and arms.

As we hit the 70s, the seats started to lengthen and were made of timber ply as crews started to lengthen out the stroke. Crews used a range of methods to slide on the timber seats, including wearing shorts coated in Vaseline, shorts with a Shammy type material stitched to the seat and even some used Pantihose over sluggos and ultimately sluggos with detergent on the seat became the transition to simply using water as the seat finish improved. Today’s shop production fibreglass seat didn’t make its entrance until the 80s.

Acknowledgements

A very good document detailing more history and many other aspects of surfboat rowing can be found at http://www.surfboatdirections.com.au written by Kim Marsh.

Also available by Kim: Timber Heritage Surf Boats 1947 to 1971

More history is to be found on the ASRL website: www.asrl.com.au, that has been contributed and authored by Michael King of the Newport Surf Club.

Newport SLSC Sweeps Michael King and Robert Emerson

The Gus McDonald era of South Coast Surfboats will soon be available on the Broulee Surf Club website for viewing.

Thanks to all those that contributed with photos and information including various websites:

Don McManus, Stephen Blewitt, Matt Clymer, Nathan Perry, Richard Olesinski, Richard Meadmore, John Wright, Neil (Twisty) Oliver, Peter Morey, Mike Taylor, Michael King, Pittwater Online News, Les Irwig, Warwick Archer, Robert (Daffy) Gray, Barry Duhne, Les Irwig, Bernard Duncan, Joe Weston, Garry Claypan, Grant Wilkinson, Gus McDonald, Gary Pettigrove, Kim Marsh and Surfboat Directions, Peter Taylor, Jase Bean, Michael Rees, Rob Burgess, Gary (Herb) Staples, Damien McSkimming, Brendan MacAlpine, Terry Owens, Barry Adams, Chris Mercer, Lofty Richardson, Graeme King, Harvey Allison, Shayne Clark, Chris Clayton, Nicolette Cartwright Chris (Ribs) Flemming.

Don McManus when Sweeping for Bilgola SLSC, now back with his original NB club, Nth. Narrabeen